[en] [fr] [ru]

LEPARAGLIDING 3.25 "Jardins"

USER MANUAL

1.

INTRODUCTION

2.

GENERAL CONCEPTS

3.

FILES ASSOCIATED WITH THE PROGRAM

4.

HOW TO WORK WITH THE PROGRAM

5.

COMPOSITION OF THE AIRFOIL FILE

6.

COMPOSITION OF THE INPUT DATA FILE leparagliding.txt

SECTION

1: GEOMETRY

SECTION

2: AIRFOILS

SECTION

3 : ANCHOR POINTS

SECTION

4: LIGHTENING IN THE RIBS (RIB HOLES)

SECTION

5: SKIN TENSION

SECTION

6: SEWING

ALLOWANCE

SECTION

7: SEWING

MARCAGE

SECTION

8: ESTIMATING THE GENERAL ANGLE OF ATTACK

SECTION

9: DESCRIPTION OF LINES

SECTION

10: BRAKES

SECTION 11: RAMIFICATIONS LENGTH

SECTION 12: H V and

VH RIBS

SECTION 15: EXTRADOS

COLORS

SECTION 16: INTRADOS

COLORS

SECTION 17: ADITIONAL

RIB POINTS

SECTION 18: ELASTIC

LINES CORRECTION

SECTION

19: DXF LAYERS NAMES

SECTION

20: MARKS TYPES

SECTION 21: JONCS DEFINITION (NYLON RODS)

SECTION 22: NOSE MYLARS DEFINITION

SECTION 23: TAB REINFORCEMENTS

SECTION 24: GENERAL 2D DXF OPTIONS

SECTION 25: GENERAL 3D DXF OPTIONS

SECTION 26: GLUE VENTS

SECTION 27: SPECIAL WINGTIP

SECTION 28: PARAMETERS FOR CALAGE SPEED AND TRIMER STUDY

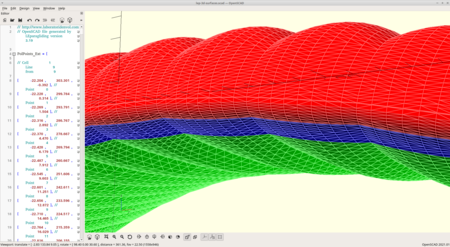

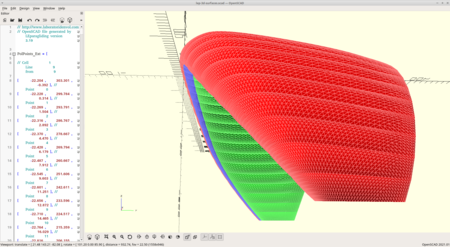

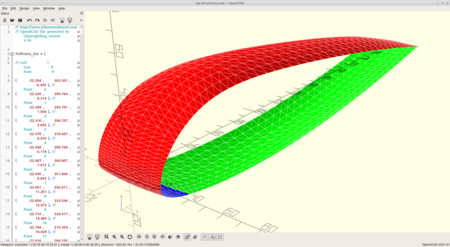

SECTION 29: 3D SHAPING

SECTION 30: AIRFOIL THICKNESS MODIFICATION

SECTION 31: NEW SKIN TENSION

SECTION 32: PARAMETERS FOR PARTS SEPARATION

SECTION 33: DETAILED RISERS

SECTION 34: LINES CHARACTERISTICS TABLE

SECTION 35: SOLVE EQUILIBRIUM EQUATIONS

SECTION 36: CREATE FILES FOR XFLR5 ANALYSIS

SECTION 37: SOME SPECIAL PARAMETERS

7. RESULTS

Interpretacions of lines labels in lines.txt

8. NEXT DEVELOPMENTS

FIGURE

INDEX

1. INTRODUCTION

This manual

describes the use of LEparagliding created by Laboratori

d'envol for the design of paragliders. The author of the program

provides no other information as described in the web. There is no

warranty for the correct operation of the program. You assume the full

consequences of use of the program.

LEparagliding

is very "cryptic" to use, "FORTRAN style", but very powerfull. FORTRAN

is a programming language aimed at numerical calculation, which means

FORmula TRANslation. It is a language that allows us to accurately

translate the ideas of geometry and mathematics to a code that produces

amazing graphical and numerical results.

The program implements the theoretical developed in the book "Paraglider Design Handbook", which is advisable to study, because many of the contents are complementary.

I apologize, because this manual provides explanations in a style slightly rough. It is possible that some subjects are poorly explained. I will be happy to provide further clarification by pm. The program is not perfect, but it works.

Please, forgive my writings in English, not good enough, beacuse is not

my usual language!

2. GENERAL CONCEPTS

LEparagliding is

a calculation engine written in GNU FORTRAN language, that performs the

reading the data of the input files, and writes the results to the output

files.

Input

files:

leparagliding.txt

Contains

detailed geometric definition of the entire paraglider. The designer

must edit this text file to achieve the desired results.

airfoil1.txt

airfoil2.txt

...

They contains

coordinate files of the profiles, taking a unit chord. Can be assigned

a specific profile name of each rib. However the most common is a

general airfoil

aplied to tthe entire wing and a zero thickness airfoil for the last

profile of the wingtip,

Output files:

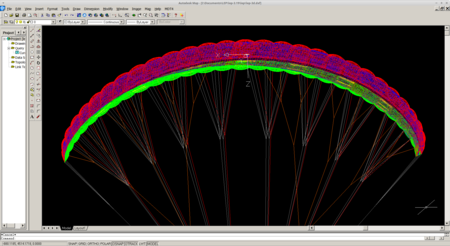

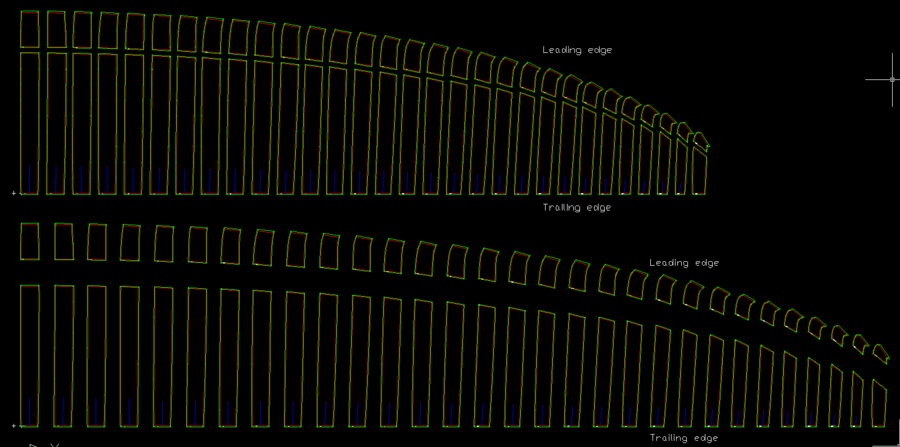

leparagliding.dxf

Contains

drawings in DXF format to be visualized. analyzed and edited with a CAD

program (LibreCAD, Autocad, Microstation...)

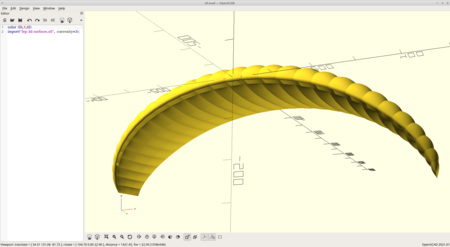

lep-3d.dxf

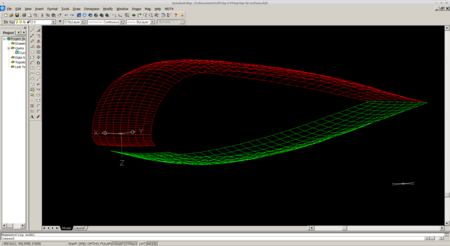

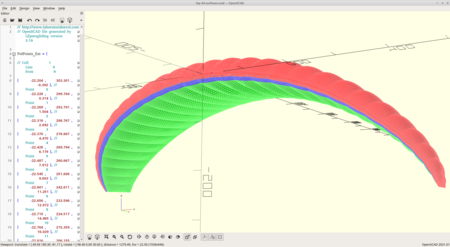

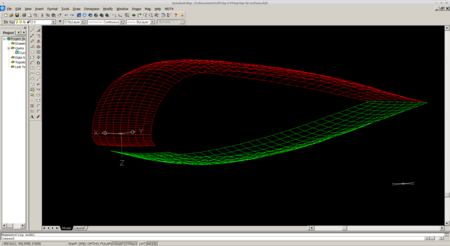

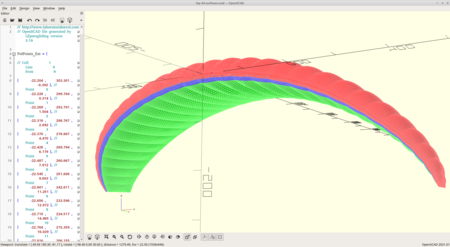

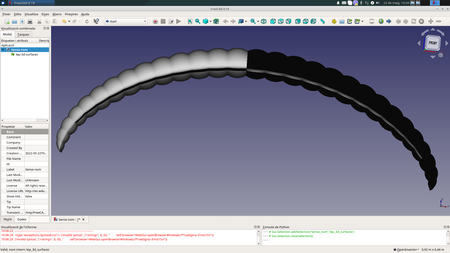

Dxf file created

automatically by the program and contains 3D model (use 3D CAD program to view)

lep-out.txt

Text

output file with the main parameters calculated on the wing (span,

area, aspect ratio, finenesse, ...) and the ordered list of the lengths

of

all lines in the wing (main line plans and brakes).

lines.txt

Text output file including the list of all lines labeled in a human readable format.

3.

FILES ASSOCIATED WITH THE PROGRAM

leparagliding.f

File program

source code, written in language "GNU Fortran 77". This file is not

necessary for the end user. Is included for developers who want to make

modifications, improvements and extensions to the code, or for

students. These

changes are completely free under the principles and conditions of the

GNU General Public License 3.0 (http://www.gnu.org) which is

distributed the program.

The

author of the file leparagliding.f program keeps it evolving and

improving, as are several important aspects to implement and enlarge

the use and possibilities of the program. Adjustments are also made to

particular designs.

leparagliding.txt

Text file that

contains the main geometric definition of the glider model, whose

detailed description is made below.

gnua.txt, gnuat.txt

Text files

containing the coordinates of the profile used. There may be many files

you want to use many different profiles (possible apply a different profile in each rib,

although that is not common)

lep-X.XX.out

(Linux) or lep-X-XX.exe (Windows)

Executable

program that must be activated to read the data and obtain graphical

and numerical results. Where

X.XX is the numericat index of the version. The name can have a suffix

specifying the version of the operating system for which it has been

compiled.

leparagliding.dxf

Dxf

file created automatically by the program and contains all drawings of

the

wing panels with patterns ready to print or further postprocess in a

CAD

program.

lep-3d.dxf

Dxf file created

automatically by the program and contains 3d model.

lep-out.txt

Text file with

the numerical results of the program.

lines.txt

Text output file including the list of all lines labeled in a human readable format. Note that some paragliders require experimental adjustments of the lengths of the lines compared the theoretically calculated (BHL1 is the case).

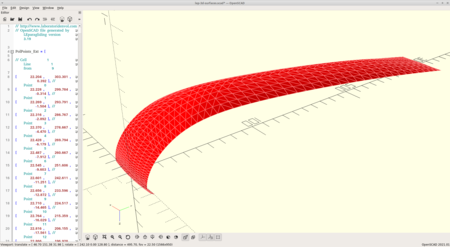

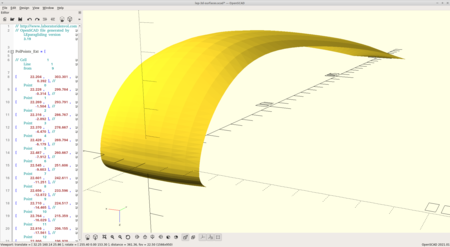

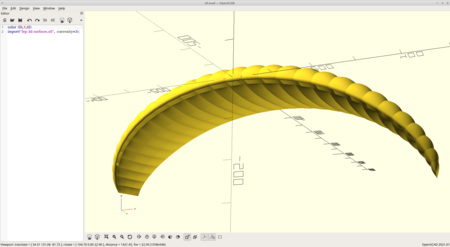

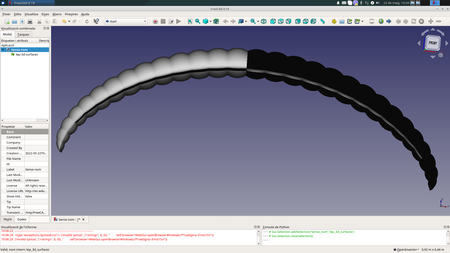

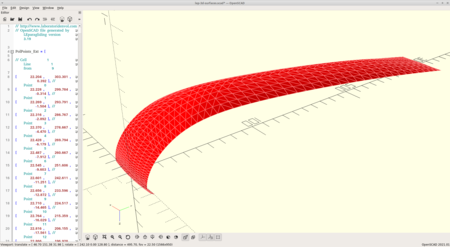

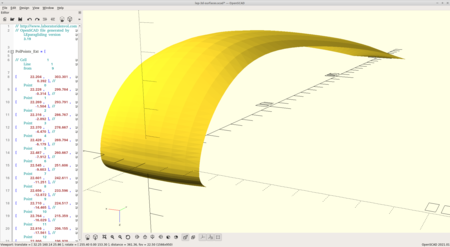

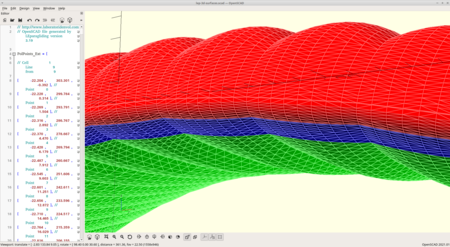

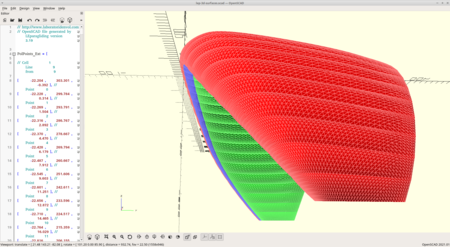

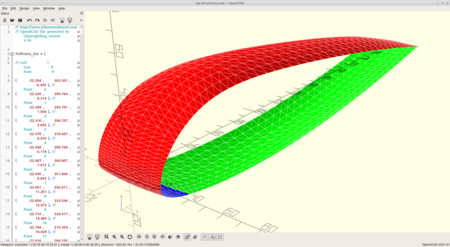

lep-3d-surface.dxf

Dxf file created

automatically by the program and contains 3d model of the wing surface including ballonement. Still not active.

lep-3d-surface.stl

STL

file created

automatically by the program and contains 3d model of the wing surface

including ballonement. STL file format will be used to visualize in 3D

modelling programs like OpenSCAD and FreeCAD. Still not active.

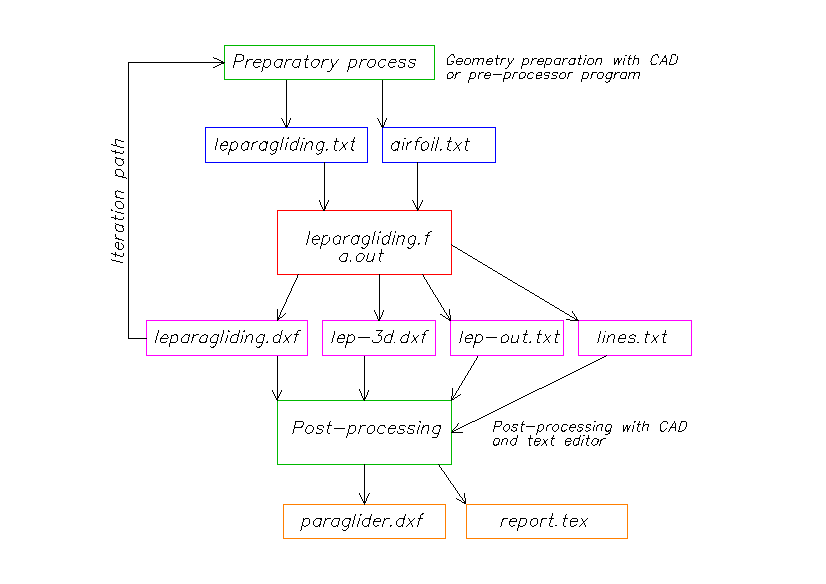

4.

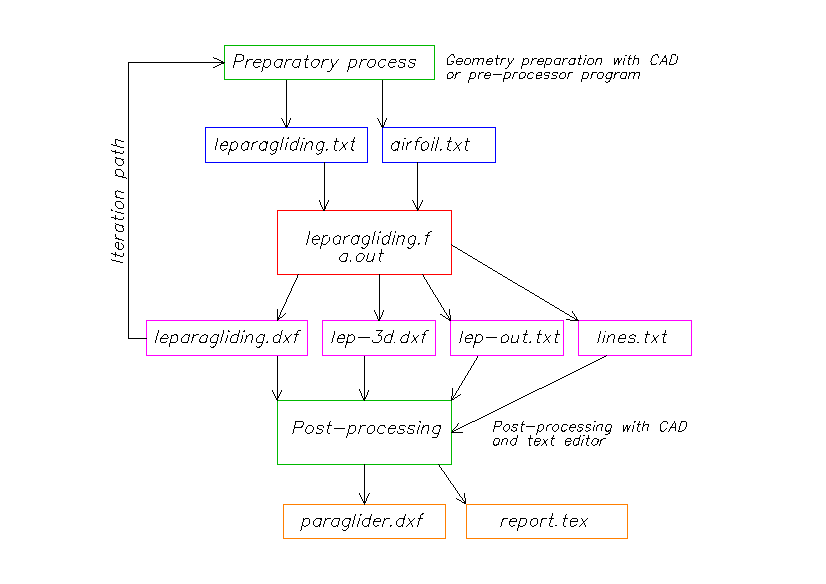

HOW TO WORK WITH THE PROGRAM

Working with

LEparagliding consists of the following phases:

1.

Pre-process

It

is the initial phase of design, whether using CAD or pencil and graph paper

and calculator. It defines the shape in plan, the lobe or vault and the

desired inclination of the ribs. Note

that the pre-process work with paper, pencil, calculator and definition

of discrete

analytic functions, enables the same precision as with CAD.

An

analytical pre-processor is available (is optional, and not strictly necessary), but very practical.

2.

Edit data file

Descibed below in detail. Complete sections 1 to 31.

It is the most important

operation, and the overall design

of the glider

itself

3.

Program execution (seconds)

GNU/Linux:

run ./lep-X.XX.out in a

terminal

Windows: execute lep-X.XX.exe

including one or more compatible cygwin .dll's in the same directory.

Mac OSX: compile sorce code in a terminal: " f77 leparagliding.f" and

run "./lep-X.XX.out" in terminal as in linux

(compiler name will be f77, g77, gfortran, or equivalent). Not tested

yet.

4.

Viewing the drawings (CAD)

The

program CAD displays the results dxf file. Please use 'zoom_extension'

command.

5.

Iteration from stage 1. to achieve the desired layout.

6.

Post-process CAD

Drawings

can be edited by the CAD program to improve the presentation. They

should position the panels and ribs on a reference template and print

the templates in an array of A4/A3 size paper or plotter.

FIGURE 1: How to

work with the program.

Since 2.23 version and additional file lines.txt is in the output.

5. COMPOSITION OF THE AIRFOIL FILES

The file of the

profile data must have the following structure:

Line 1: name of

the profile

(do not use spaces in the name)

Line 2: total

number of points defining the profile

Line 3: number

of points that form the extrados

(upper surface)

Line 4: number

of points that form the opening (if any)

Line 5: number

of points that form the intrados (lower surface)

Following lines:

X coordinate Y

coordinate of each point of the airfoil

The

coordinates are ordered starting at the trailing edge, covering the top

surface, passed through the leading edge and coming through the lower

surface and

again ending at

the trailing edge.

Important: The endpoint of the

extrados must exactly match the start in% of the opening (air inlet),

and the

starting point of the intrados must exactly match the end in% of the

opening (air outlet). Therefore the airfoil must be processed prior in

a CAD program

to

achieve this. Therefore if you want to vary the start and end points of

the air openings along span, you must detail specific profiles

for this.

Init and

end points of openings declared in leparagliding.txt file must be

consistent with the selected airfoils.

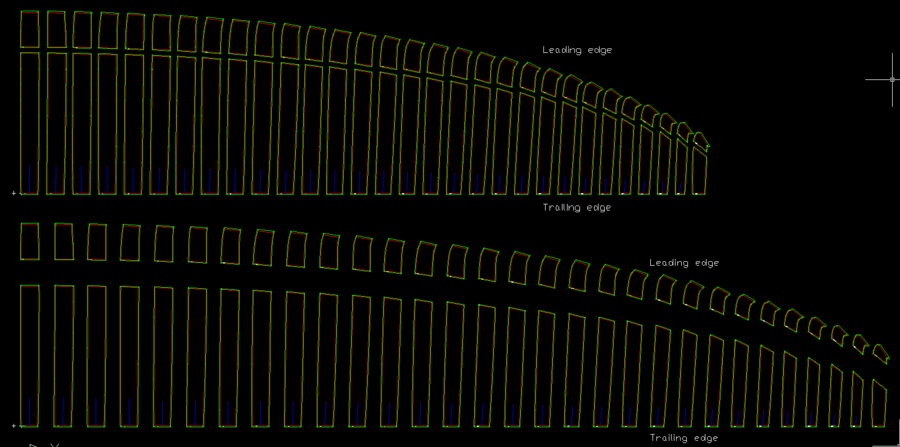

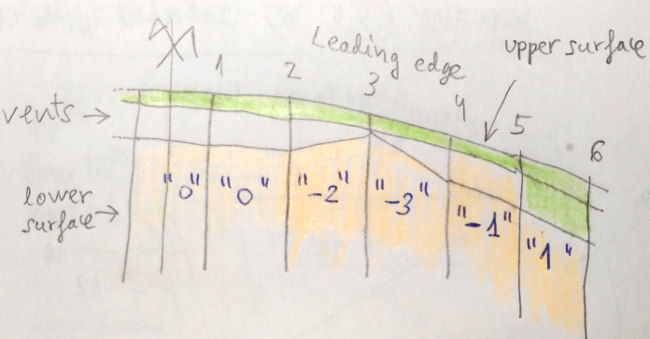

FIGURE 2:

Airfoils definition

For gnulab2 two

profiles have been defined eg for gnulab2.txt wing and

airplan.txt to the end profile.

It

is essential that the number of points of extrados, openings, and

intrados,

and all are exactly the same for all profiles defined in a

wing

model.

The maximum number of points allowed per profile is 500.

Zero-thicknees wingtip airfoil:

Usually, you must

define a profile of zero thickness for the final profile of the

wingtip.

It is advisable to move the end of the panel's top surface (upper panel) to 0% of the profile, and keep the same number of points for each item (upper panel "extrados", air intakes, bottom panel "intrados").

Closed cells:

The program apparently only works with open cells. But it also draws all caps cloth inlets that can be added manually (with a CAD program), the underside of the panels. Thus, any cell can be closed or converted to a special opening of any geometric shape. Recent versions have various cell types.

6.

COMPOSITION OF THE INPUT DATA FILE leparagliding.txt

Designing

the paraglider is simplified to editing the file leparagliding.txt

either

creating it from scratch or by editing an existing model.

All

lines that begin with the symbol "*" are comments that are not used by

the program, although

you must maintain it to keep the sequence of

reading.

It is not allowed to add blank lines.The

main units planned for the data file are centimeters (cm), except

sewing

allowances in section 6, and some values in section 20 and 21 will be expressed in mm. Optionally,

you could use inches and tenths of inches, but this has not been tested

ever.

Next,

and

by section, we define the parameters to

enter in the data file.

Only are explained the line to complete, because the lines that begin with the asterisk

symbol * are comments that should be maintained as are, so that the

reading order is right.

First, it

indicates the type of data

to

enter (integer, real , text, or boolean (1 or 0)). Then, following the ":" , indicates

the object's data to write. It is

essential using

the sample file leparagliding.txt to

understand. The order, data type, and number of rows is essential for a correct reading

of the

data file.

SECTION

1: GEOMETRY

By lines, and regardless of the lines beginning with *

which are comments

or notes for help.

text

: Brand name

(between " ")

text

: Wing name

(between " ")

real : Drawing

scale (1.0 usual value)

real : Wing

scale (1.0 usual value)

integer

:

Cells number

integer :

Ribs number

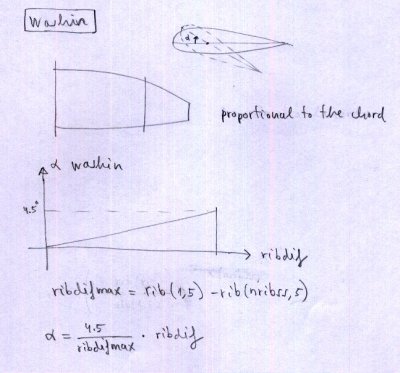

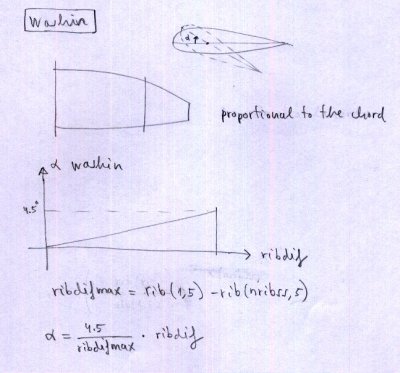

real, integer, real

: Maximum torsion

angle

(washin) between central airfoil and tips, an integer parameter set to

0-1- 2, and a real number for the angle of attack in the center used

only in case "2".

If

the integer parameter is set to "0" the washin will be done manually. (Figure 3).

If the integer parameter is set to "1" then washin will be done proportinal to the chord, being maximun and positive at the tip, using only the first real.

If the integer parameter is set to "2",

then automatic washin angles are set from center airfoil to wingtip.

The first real is the washin in wingtip, then set "2", and the last

real is the washin in the central airfoil.

Example about how to use: Below line 21 in leparagliding.txt data file:

* Alpha max and parameter

3.5 2 -1.0

- First number "3.5" is the angle of attack (degres) in wingtip airfoil

- Second number "2" is a control parameter

that means case "2", ie, add new number indicating the angle of attack

of the central airfoil

- Third number "-1.0" is the angle of attack (degres) of the central airfoil

The distribution angles of attack is made

proportional to the wing chord (similar to case "1"). See "lep-out.txt"

to view the result.

text,

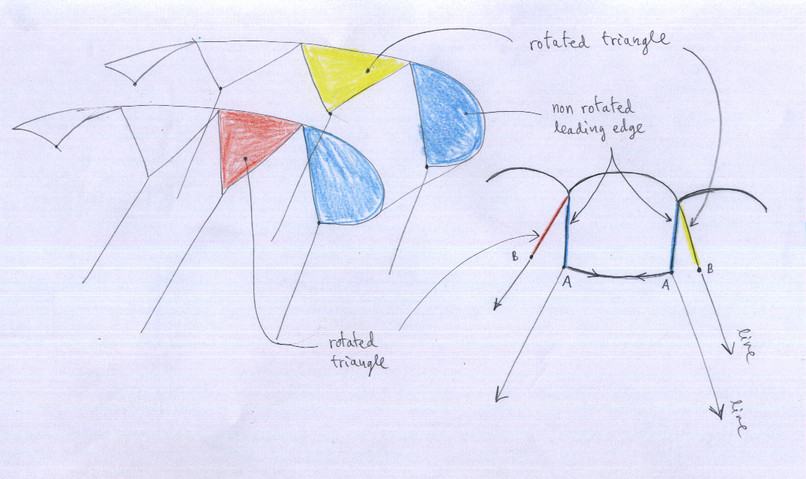

boolean : Paraglider type "ds", "ss", or "pc", and parameter set to 0

or 1. If

1

then leading edge triangles will be no rotated (only ss paragliders)

integer

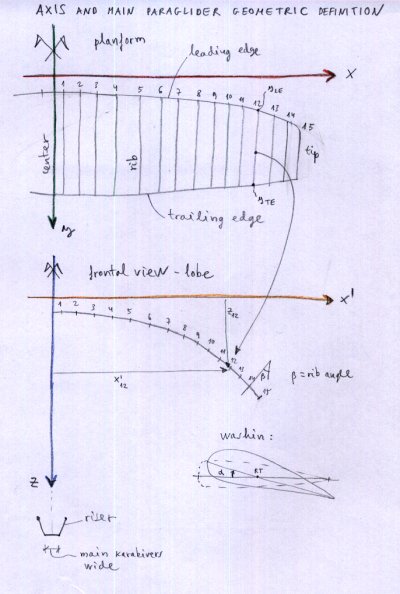

+ 10 reals:

For

each of the ribs, and considering an orthonormal system of axes XYZ

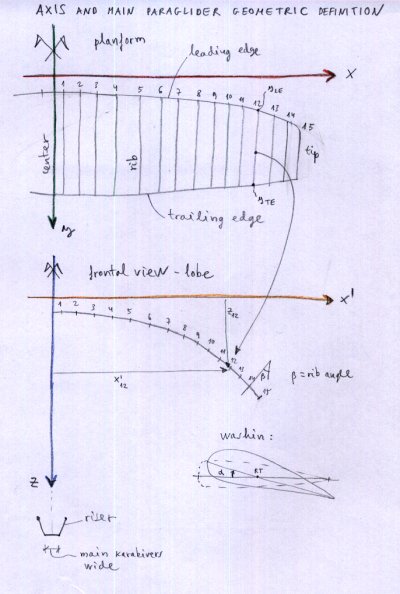

(Figure 4) .

oriented

in the following way:

X

axis along the wingspan

Y

axis along the central chord

Z axis growing vertical from the wing to the pilot

They are shown

in a horizontal line the following 11 parameters:

integer

: rib number

real

: rib X

coordinate

real

: Y

coordinate of the leading edge

real

: Y

coordinate of the trailing edge

real

: X' coordinate

of the rib in its final position in space

real

: Z coordinate

of the rib in its final position in space

real

: the angle

"beta" of the rib to the vertical (degres)

real

: RP percentage

of chord to be held on the relative torsion of the airfoils

real

: washin in degrees defined

manually (if parameter is set to "0")

And since version 3.15z, you MUST add two additional parameters:

real

: angle of rotation of the profiles with respect to a vertical axis Z (degrees).

real

: numeric value expressed as a percentage of the chord, where to place the vertical axis of rotation of the profiles

These

parameters can not be defined without a previous drawing, preferably in

a file of computer aided design CAD, in which the desired plant is

drawn to an appropriate scale, form lobe in elevation, and inclination

of the ribs. This drawing is one of the most basic and important design

(pre-process).

It

would be possible to generate this drawing by a geometric preprocessor

to read basic data from the wing desired number of cells, separation,

size, shape, edge and trailing by a few parameters defined to create

elliptical shapes. This

pre-processor has been implemented (june 2013), but not inside the main program, because we prefer

to keep this

important part of design with a CAD program, to allow total freedom of

the shape of the leading edge, trailing edge, and in the elevation, and

inclination of

the profiles. Any design is possible, normal wings, or bionic type,

with peaks in leading edge or ...

There is a

limitation of not being able to define airfoils in the center of

symmetry. To remedy this situation can be defined a virtual central

cell's with almost zero thickness.

Figure 3. Washin

Figure 4. Axis

and main paraglider geometric design

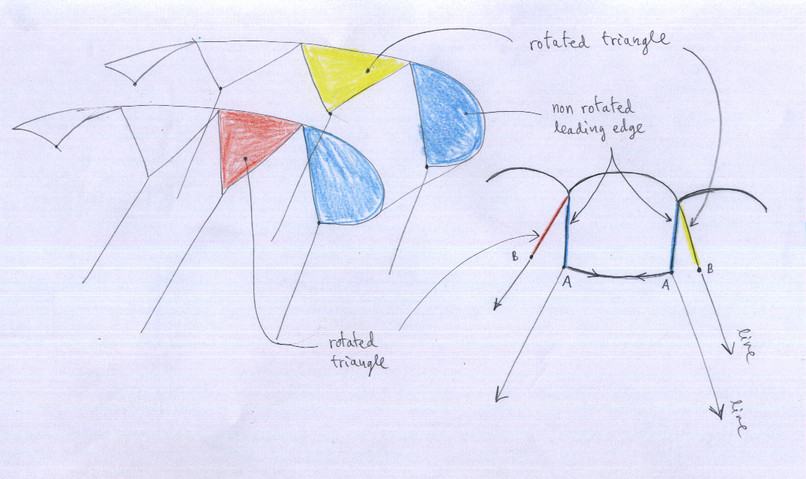

Instructions for selecting the type of paraglider (parameters "ds" "ss" "pc" listed above):

"ds": means that the design and calculation parameters are adjusted to create paragliders and parachute of double surface airfoils (intrados and extrados)

"ss": means that the design and calculation parameters are adjusted to create single skin paragliders and parachutes, Surfaces corresponding to the intrados are not draw. But it is not enough to indicate this parameter to create single skin paraglider. It is necessary to define an special intrados sawtooth profile (or parabolic shaped), so that the vertices of the triangles are located exactly at the point where% is defined the anchor points. As a general rule, we use covers of the air intakes, as part of the sigle skin profile.

"pc": means that the design and calculation parameters are adjusted to create parachutes using double surface airfoils (intrados and extrados).

Maximun alloved number of ribs is 100 per side (200 ribs or 199 cells).

Figure 5. Only

in "ss" paragliders, the parameter set to 0

or 1. If

"1"

then leading edge triangles will be no rotated. Control over specified

ribs will be done using a real parameter 0.0 or 1.0 in last column of

section 2, as explained below.

SECTION

2: AIRFOILS

In an orderly

manner for each rib, are written in a horizontal line:

integer : Number of rib

text : Name the file

containing the airfoil assigned to that rib

real : Percentage of

chord start of the air inlet

real : Percentage of chord end

of

the air inlet

boolean :

Value 1 or 0 to

create

closed cells, at the left of rib ("0" indicates closed-cell, "1" open)

real

:

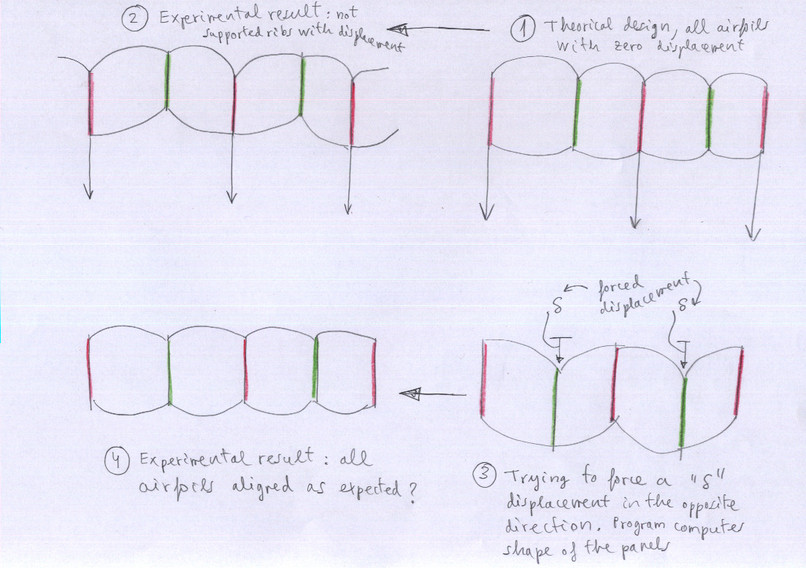

Displacement in cm of the rib

perpendicular to the chord,

and in the plane of the

rib itself.

Serves to

improve the position of the ribs without suspension lines. Value

is usually 0

real:

Relative

weight of the chord,

in relation to the load. Value

is usually 1.

real: It has two meanings:

1) If values is "0" or "1", only used in single skin paragliders (useless in double skin). More control in rotation of triangles. Real value "1" (or "1.") means that the triangles are rotated automatically in the corresponding profile. "0" means that the triangles are not rotated, but they are set according to the angle "beta" specified in Section 1.

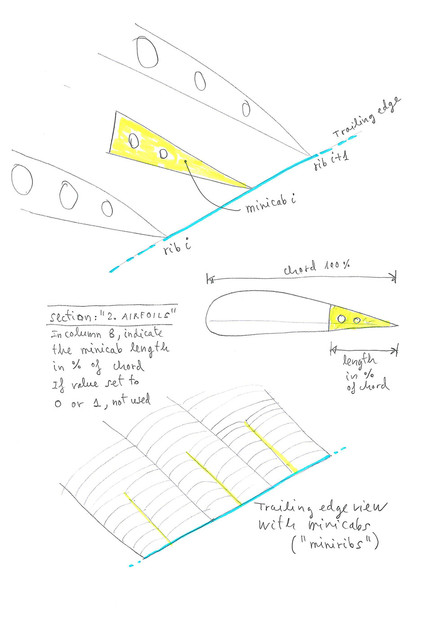

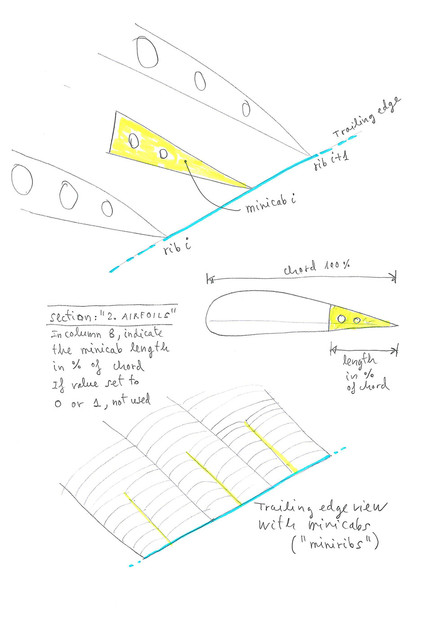

2) If the numerical value greater than 1.0 is possible define and draw trailing edge "miniribs" ("minicabs")

in non "ss" paragliders: The value, simply define the minirib length (in %).

Figure 6. Miribs definition in lep < 2.50 (since lep-2.50 minirib "i" was defined at LEFT, between "i-1" an "i")

Note:

init and end points of the air openings are not fully implemented yet in the program, and is in the profile itself obliged

to include it means of the integer numbers that describe the end of the top surface and the beginning of the intrados (in each airfoil).

MIDDLE

UNLOADED RIBS: Added the possibility of using "middle unloaded ribs".

Very easy to use: In section "2. AIRFOILS" at the last column use the

parameter "100", means to place a complete unloaded rib in the middle

of the panel, and the left corresponding rib. Similarly, as defined in

the mini-ribs. But the parameter "100" activates a new specific

programation. New plan numbered "1-6" with the new middle ribs numbered

and marked. These ribs have been reformatted to achieve a perfect match

with high precision, with the corresponding panels. In the center of

the panels, are marked equidistant points in correspondence with the

middle unloaded ribs. In addition, in the 2D-planform (plan "1-1"),

also drawn in gray new ribs. Planned to draw in 3D (for reference) but

not yet done. Important: To define holes in the ribs (elliptical or

circles), add in section "4. AIRFOIL HOLES" a new hole type "11" that

is defined exactly as the type "1" (hole type "1" and type "11" are

exactly the same but the type "11" used exclusively by the middle

unloaded ribs). In this case the initial rib number and end rib number

with holes type "11" should be the same, and greater than the maximum

number of ribs on one side, for example, use "50" . See the attached

example "leparagliding.txt". All new programation in section 9.9 of the

source code.

-

"Mini-ribs" are redefined, and now in section "2. AIRFOILS" at the last

column, if you use the parameter "15", means to place a 15% mini-rib in

the middle of the panel, and at the LEFT of the corresponding rib.

Previously (lep < 2.50), mini-rib it was placed on the RIGHT. But it is better set

at the left, so you can specify a minirib the center of the wing

(Mini-rib specified in the left first rib). And this is consistent with

the new middle unloaded ribs.

-

Applied little optional displacement (to the center of the wing) in the

points marking the position of the miniribs. Third parameter in the

line of section "7. MARKS" of the datafile. Before, this displacement

was set to default to zero.

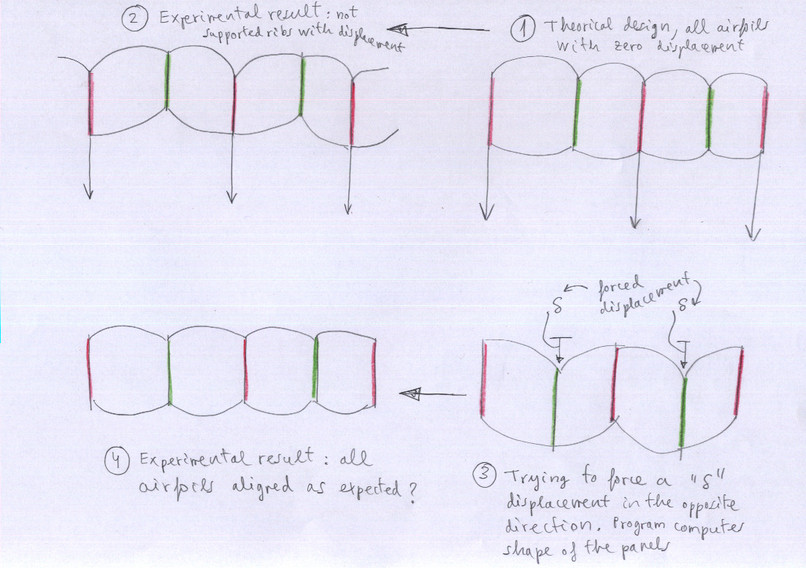

Figure 7. Interpretacion of parameter in sixth column. Parameter "delta" = forced displacement in cm of the rib perpendicular to the chord,

and in the plane of the

rib itself.

SECTION

3: ANCHOR POINTS

In an orderly

manner for each rib, are shown in a horizontal line:

integer

: Number of rib

integer

: Number of

anchors in the rib

real

: Anchor position

A as% of rib

real

: Anchor position

B as% of rib

real

: Anchor position

C as% of the rib

real

: Anchor position

D as% of rib

real

: Anchor position

E as% of rib

real

: Anchor position

F as% of rib

Note: A, B, C,

D, E anchorages. F brakes.

SECTION

4: LIGHTENING IN THE RIBS (RIB HOLES)

By Rows:

integer : Number of

configurations of lightening

integer : Initial rib for

first lightening configuration

integer : Final rib for

first lightening

configuration

integer : Number of holes for

the first

lightening configuration

Definition of

each hole in a horizontal line. There are three possible types of holes. Type 1 = elliptical holes (including circulars),

type 2 = elliptical

holes central band, type 3 =

triangular holes with

smooth corners.

If the

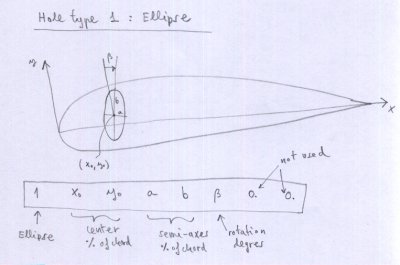

hole is type 1, type

in a horizontal line:

integer : 1

real : Distance from LE

to hole center in% chord

real : Distance from

the center of hole to the chord line in% of chord

real : Horizontal axis

of the ellipse as% of chord

real : Ellipse vertical

axis as% of chord

real : Rotation angle

of the ellipse

real : 0. (not used)

real : 0. (not used)

real : 0. (not used)

Figure 8. Hole type 1, ellipse

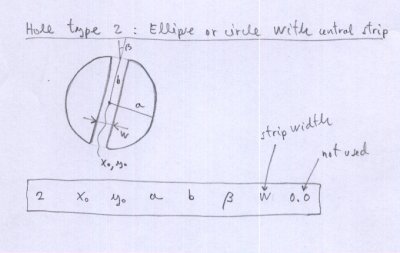

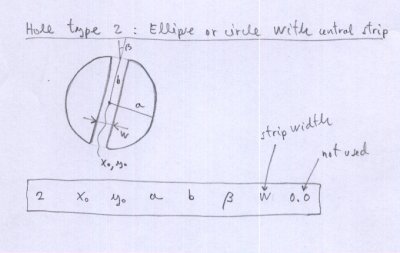

If the hole is type 2, type in a horizontal line:

integer : 2

real : Distance from LE

to hole center in% chord

real : Distance from

the center of hole to the chord line in% of chord

real : Horizontal axis

of the ellipse as% of chord

real : Ellipse vertical

axis as% of chord

real : Rotation angle

of the ellipse

real : central strip width

real : 0. (not used)

real : 0. (not used)

Figure 9. Hole type 2, ellipse or circle with central strip

Not use holes type 2 beacuse yet no

implemented !

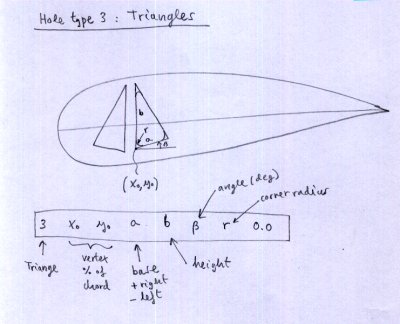

If the hole is type 3, type in a horizontal line:

integer : 3

real : Distance from LE

to triangle in% chord

real : Distance from

the center of the triangle corner to the chord line in% of chord

real : Traingle base as% of

chord

real : Triangle heigth as% of

chord

real : Rotation angle

of the base

real : Radius of the smoothed

corners

real : 0. (not used)

real : 0. (not used)

Figure 10. Hole type 3 triangle

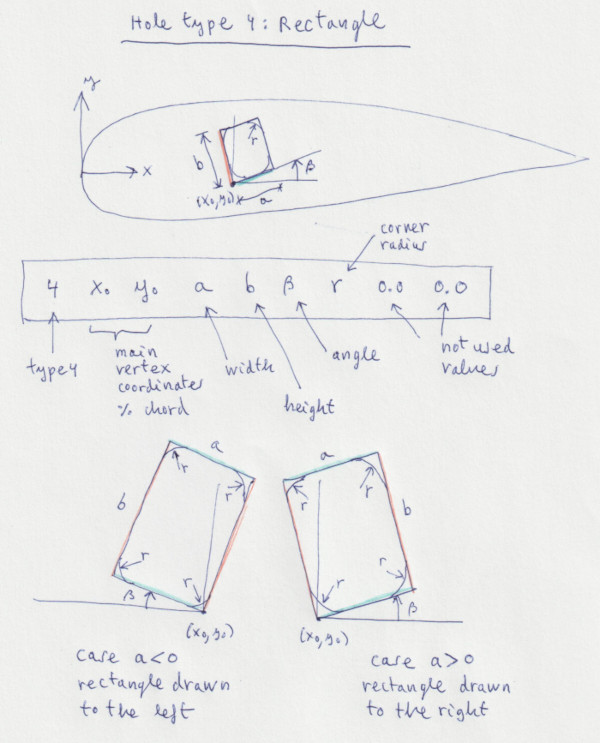

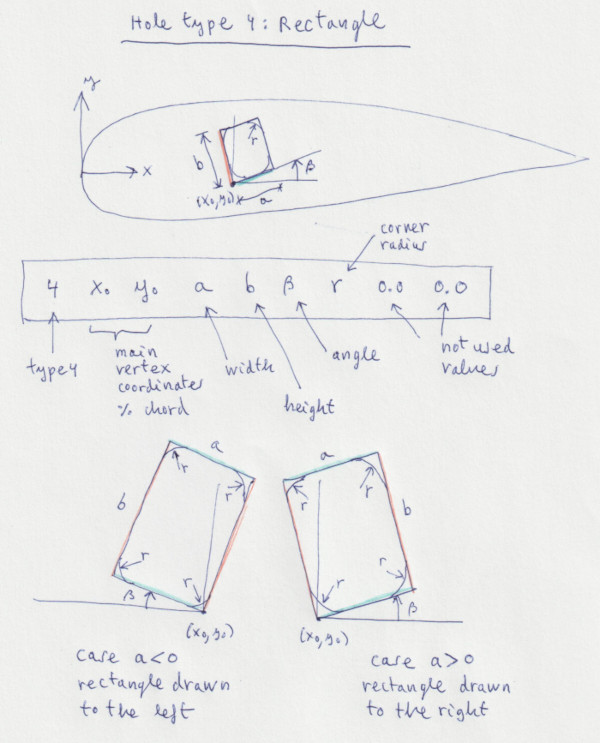

If the hole is type 4, type in a horizontal line:

integer : 4

real : x Distance from LE to main rectangle corner in % of chord

real : y Distance from chord line to main rectangle corner in % of chord

real : a rectangle width as % of chord

real : b rectangle heigth as % of chord

real : Rotation angle (degrees) relative to chord line

real : Radius (%) of the smoothed corners

real : 0. (not used)

real : 0. (not used)

The main vertex or reference vertex of the rectangle is the bottom left.

If the width value (a) is positive, the rectangle is drawn to the right of the main vertex.

If the value of (a) is negative, then the rectangle is drawn to the left. Similar to the case of triangular holes.

Image 10.1 Parameters for hole type 4 (rectangular)

Continue:

integer : Initial rib for second lightening

configuration

integer : Final rib for second lightening

configuration

integer : Number of holes for the second

lightening configuration

Definition of

each hole in a horizontal line, as before.

And so on... (repeat pattern

for all types of lightening configurations)

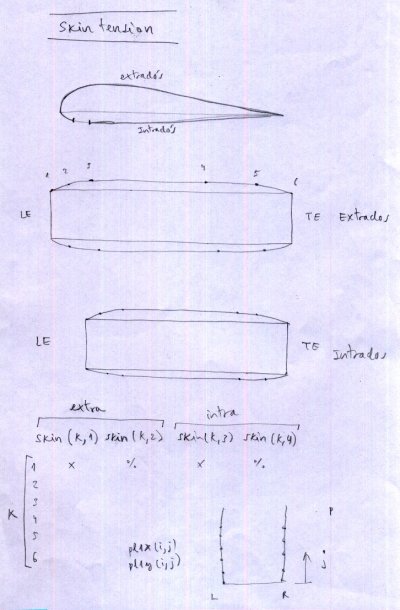

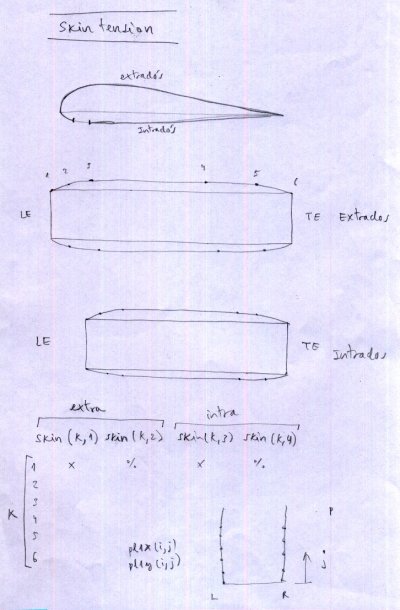

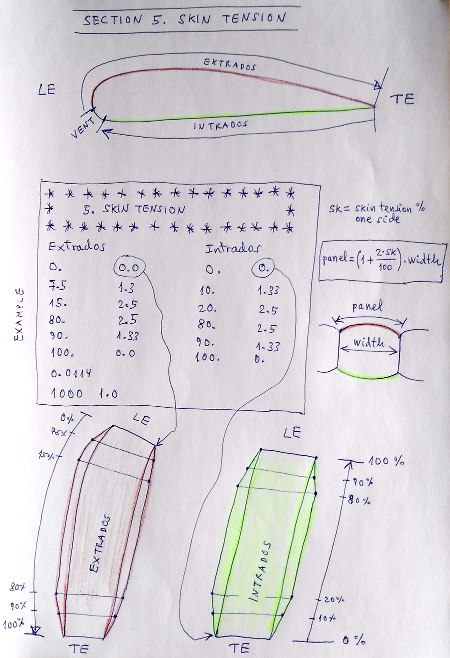

SECTION

5: SKIN TENSION

The tension of

the top surface and lower surface panels is achieved by creating tapers

in the panels. The program allows you to define "over-wides" in 6

points along the edge of the panels. The transition between basis

points of overwide is linear.

In each of the

six lines are defined to indicate consecutively:

real :

Distance in% of

chord on the leading edge of extrados

real

: Extrados

over-wide corresponding in % of chord

real

: Distance in% of

chord on trailing edge

real

: Intrados

over-wide corresponding in%

of chord

A better explanation >

|

|

FIGURE 11: Skin

tension

Then add two more lines with the

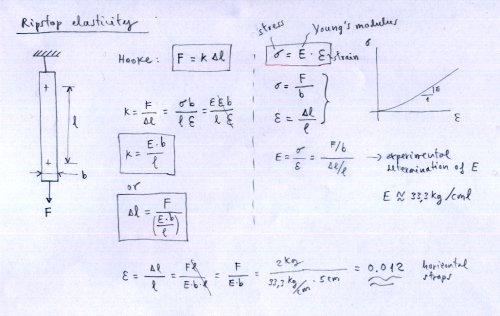

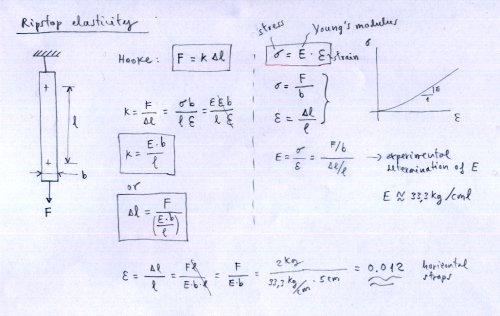

following parameterr (new in leparagliding 2.0):

real :

0.0114 (strain in

mini-ribs).

The

justification for this value is

obtained from the theory of

elasticity.

Leave the

default value in case

of doubt.

Figure 12. Ripstop

elasticity

integer, real :

Number of points np,

k coeficient 0.0 to 1.0

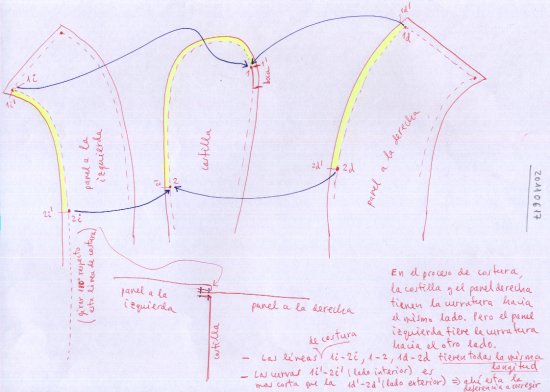

The justification for this line is complex. There are two possibles interpretations:

First interpretation)

If first number in NOT set to "1000", the values are used to make adjustments

to the shape of the leading

edge for easy sewing, using an "antiprecision" method.

However is and old feature and actually is not recomended. Study conducted at the

request of a manufacturer of paragliders. The second number is used to adjust the intensity of the modification (1.0=maximal effect, 0.0= no effect).

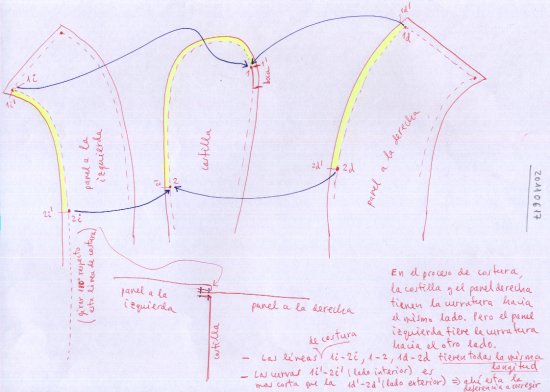

Justification

of the

line in the

figure below:

Figure

13. Sewing corrections

And the

explanation:

When three

panels are sewn at the same time, with different curvatures to side... problems

may arise:

The left panel

(i="izquierda") has a concave curvature, while the right panel (d="derecha") has a

convex curvature.

The lengths of

seam lines (line dashed) should be exactly the same. However, the outer edge of the

fabric, which is 15 mm from the seam line, is shorter in the left case

(inner radius) than the right (outer radius). The program calculates the

difference in length of the leading edge in the area of "np" points od airfoil of greatest curvature from air inlet (np defined by user).

With the

calculated length difference (1d2d-1i2i), the program modifies the plan shape of the

left panel, extending its inner side. Thus, when the seam is made, there are

fewer problems ...

The second

control parameter, "k" between 0. and 1. is the coefficient to be applied to the

difference (1d2d-1i2i). Then 0.0 = no effect. 1.0 = total effect. Then sewing

corrections:

integer, real :

Number of points np, k coeficient 0.0 to 1.0

Another explanation for the same, but in French: Étude des courbures panneaux-nervures (PDF)

Many builders prefer not to take into account this effect, then select the parameter as k=0.0

Second interpretation) Recommended for all designs

Set the parameters of the line to the values:

1000 1.0

First number "1000" (integer) is only a convention than signifies force

the program to use maximal precision, reformating panels to achieve

accuraccy better than 0.1 mm (lengths differences beetween rib and

panels located at left and right).

Second number is a coefficient (real) between 0.0 and 1.0 that sets the

intensity of the correction. If coefficient is set to "0.0" then is no

correction. If the coefficient is set to "1.0" the accuracy is maximal,

aprox < 0.01 mm.

The description of the geometrical problem and the solution, is decribed here.

In file lep-out.txt is a report in section 6, indicating the final

lenghts of the panel at left, rib, panel at right, and maximal

difference and distorsions in mm.

SECTION

6: SEWING

ALLOWANCES

3

reals : Edge seam (mm)

in upper panels, LE, TE

3

reals : Edge seam (mm)

in lower panels, LE, TE

real

: Edge seam (mm)

in ribs

real

: Edge seam (mm) in V-ribs

SECTION

7: SEWING MARCAGE

Indicate

the spacing in centimeters and the radius of the point, to make marks

on ribs and panels to match all items as accurately and thus able to

control that there is no slippage during sewing.

real, real, real : marks spacing, point radius, point

displacement

SECTION

8: ESTIMATING THE GENERAL ANGLE OF ATTACK

This

section defines the basic length of the lines and provides the general

draft of the wing, estimating the center of pressure and angle of

glide.

Be entered on

lines below:

real

: Finesse goal, according to the general proportions of the wing.

real

: Position of the wing center of pressure estimated as % of central cord

real

: Calage in% (distance from the leading edge point to the perpendicular

to the central chord from the pilot position)

real

: Riser basic length

real

: Basic length of lines (maillons - sail)

real

: Separation between main carabiners

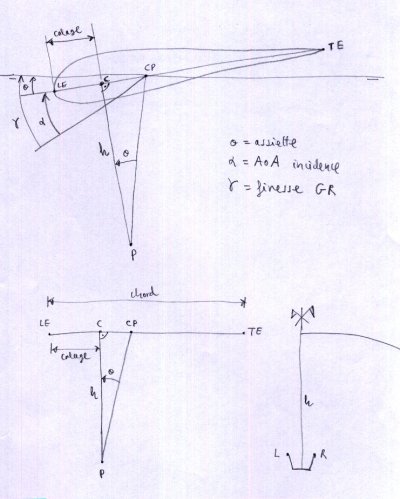

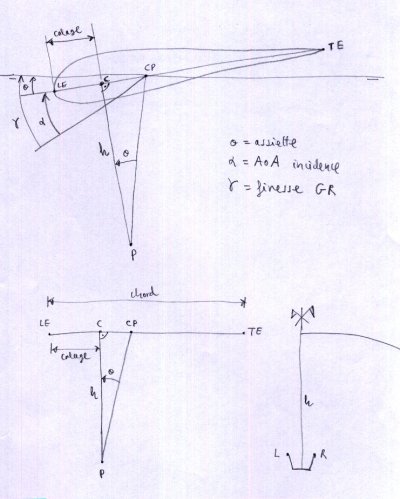

FIGURE 14:

General AoA estimation

SECTION

9: DESCRIPTION OF LINES

We define the following concepts, per lines:

integer

: Control parameter with the following meanings

0 = lower branches lined only by geometric mean of the anchor points

1 = lower branches lined by weighting type 1

2 = lower branches lined by weighting type 2

3 = lower branches lined by weighting type 3 (spanwise and chordwise optimization). Read more details here.

integer

: Line plans number (2,3,4...)

Denotes the number of plans of lines that start from each of the risers

of the glider. Will be considered as many plans as risers. The "plans"

do not necessarily have lines in a plan, and may have different

alignments anchors in various rows (pyramid lines)

integer

: Paths number for first plan

11

integers : i1, i2, i3, i4, i5, i6, i7, i8 ,i9, i19, i11

Ramifications and levels

(i1)

number of branches (ramifications) of the path

(i2) branching level 1

(i3) order at level 1

(i4) level of ramification 2

(i5) order at level 2

(i6) level of ramification 3

(i7) order at level 3

(i8) branching level 4

(i9) order at level 4

(i10) anchor line (1 = A, 2 = B, 3

= C, 4 = c 5 = D, 6 = brake)

(i11) anchor rib number

- These are considered the ramifications from to the bottom to up. The

main riser are considered the branch level "1", the next line that

starts from maillons "2", the one above is the "3" ... and so on.

- Within a branch level are numbered consecutively in the same lines

from left to right 1,2,3,

- Path: Is any path through the ramifications, upward, started in the

main carabiner and ended in a sail anchor.

- With these definitions, this section should be written the array of

lines for each plan

- The first section number indicates the number of planes to be

considered.

- The next number indicates the total number of different paths in the

plane.

- Each line of the matrix is a "path"

- If there is no level 3 or 4 is denoted by "0"

- It is only allowed up to 4 levels of branching.

integer

: Paths number for second plan

11

integers : i1, i2, i3, i4, i5, i6, i7, i8 ,i9, i19, i11

Ramifications and levels

...

Do likewise with

the other plans of the paraglider line design. The example of clear

matrix writing is exposed in gnuLAB2 data file.

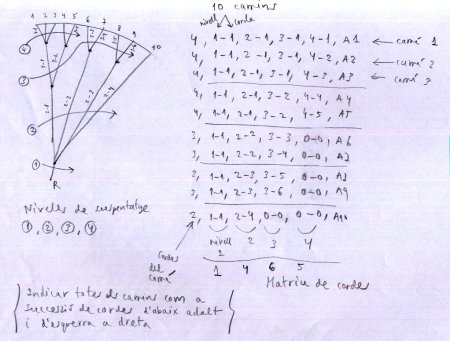

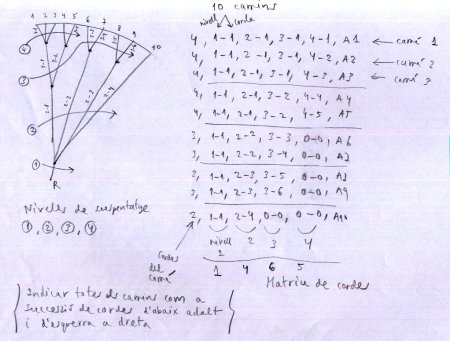

FIGURE 15:

Suspension

lines matrix

SECTION

10. BRAKES

real :

brake lenght

integer

: number of paths brake plane

The first number is the length in cm for the main brake cable, and

second number indicates the number of paths brake plane.

11

integers : i1, i2, i3, i4, i5, i6, i7, i8 ,i9, i10, i11

Ramifications and levels

Matrix writes like for the rest of the lines, taking into account that

now the level "1" corresponds to the main brake cable.

NOTE: i11 indicates rib number "i", where anchor the top line of the brakes. This number, usually an integer. Nevertheless, some versions ago was added an interesting feature. Is possible define a decimal which means the displacement of the anchoring point between the rib "i" and the rib and "i+1". For example, 8.4 means anchor the line in the trailing edge, between rib 8 and 9, and 40% from the rib 8.

Brakes distribution:

4

real : s1, s2, s3, s4, s5 (lengths along vault and from center

wing)

4

real : d1, d2, d3, d4, d5 (lengths increments in brake line)

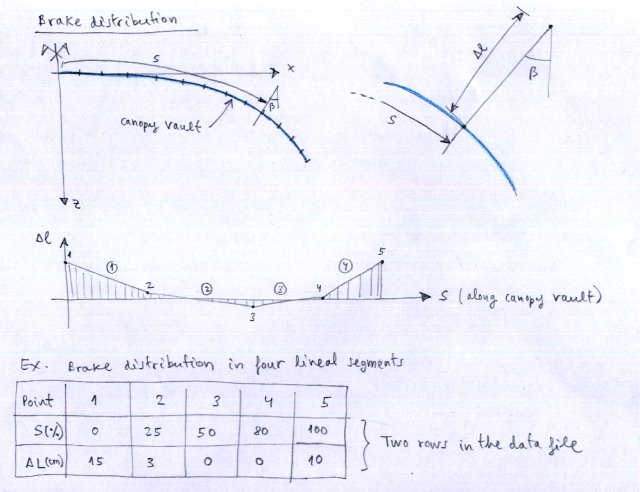

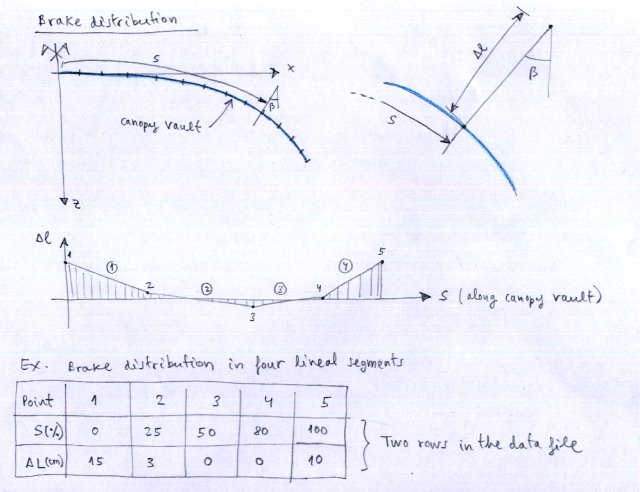

Figure 16. Brake

distribution

SECTION

11.

RAMIFICATIONS LENGTH

Indicates the

upper branch lengths to the anchors in sail, by rows:

integer, real

: 3 , Distance

branching from third ramification to sail

(l2)

integer, real, real : 4,

Distance

branching third to sail (l3), Distance

beginning of fourth branching to sail

(l2)

integer, real

: 3, Distance

beginning of third brake branch to sail

(l2)

integer, real, real : 4,

Distance

beginning of third brake branch to sail (l3), Distance brakes

start fourth branching to sail

(l2)

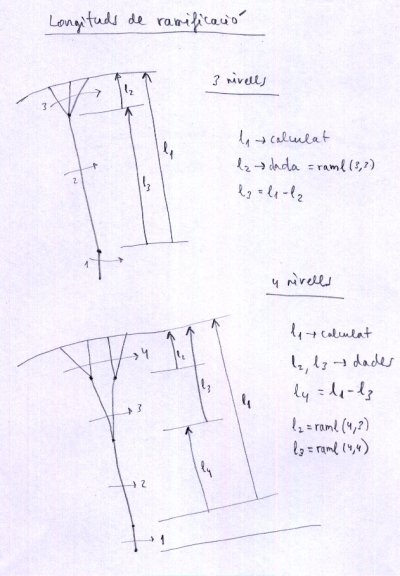

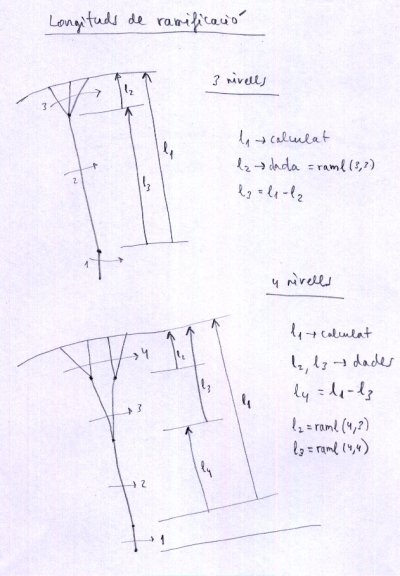

FIGURE 17:

Ramifications length

SECTION

12:

H V and VH RIBS

integer :

mini-ribs number

real, real :

x-spacing, y-spacing (when drawing mini-ribs)

Then, for each mini-rib, and in a row:

integer,

integer, integer, integer, integer,

integer, real, real real, real, real :

with the following meanings,

If it

is a mini-rib horizontal ribbon type:

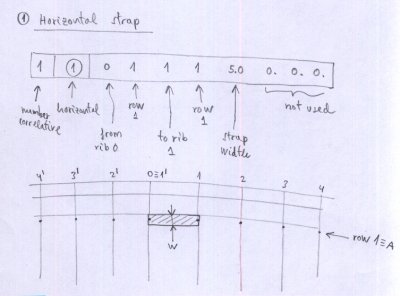

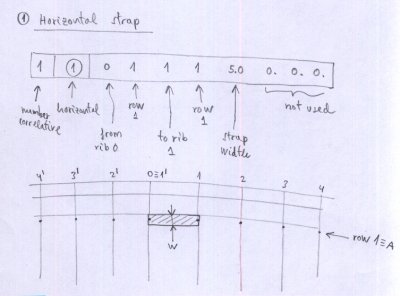

Type 1: Horizontal strap between rib i1 and rib i2

Figure

18. Mini-rib 1 (horizontal strap)

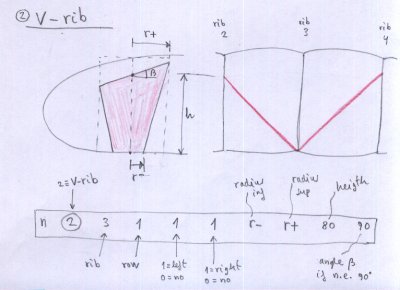

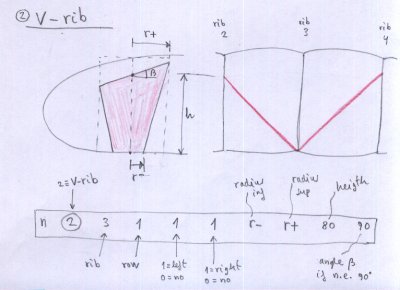

Type 2: Diagonal partial V-rib cintered in rib i

Figure

19. Mini-rib 2 (V-rib)

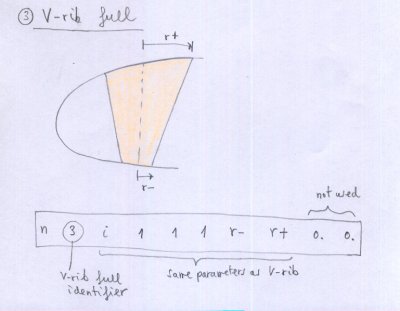

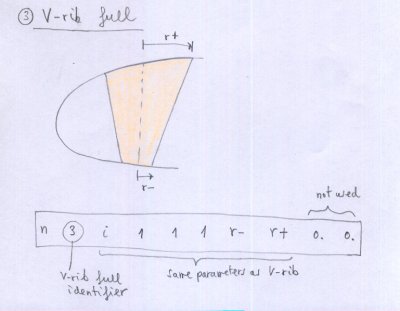

Type 3: Diagonal full V-rib centered in rib i

Figure 20. Mini-rib 3 (full V-rib

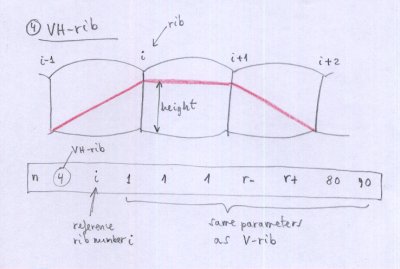

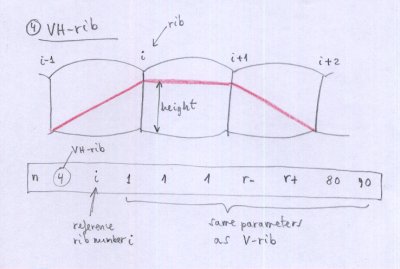

Type 4: "VH-rib" between rib i-1 to i+2

Figure 21. Mini-rib 4 (VH-rib)

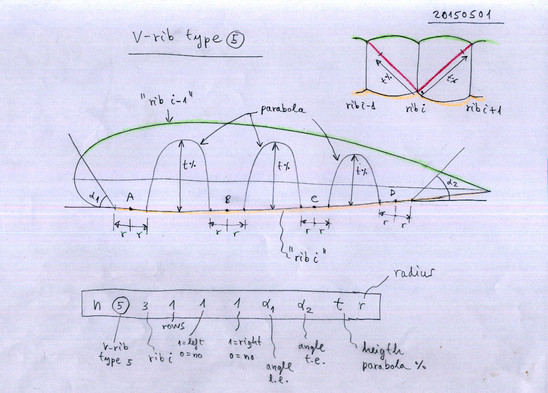

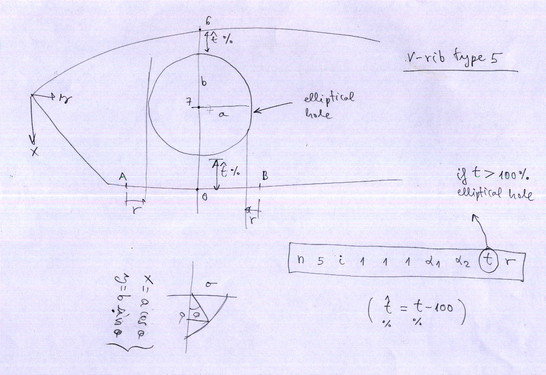

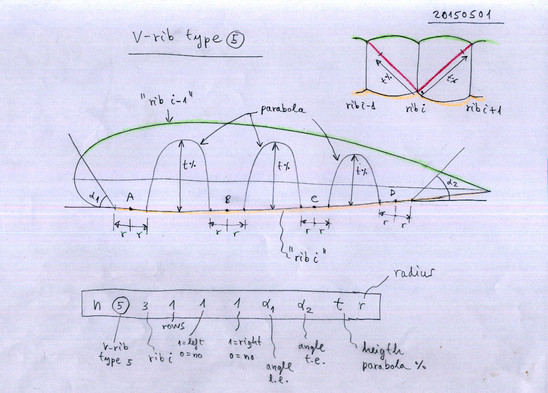

Type 5: full continous VH-rib centered in rib i

Figure 22. Full continous V-ribs type 5 using parabolic holes (if t<100%)

Figure 23. Full continous V-ribs type 5 using elliptical holes (if t>100%)

When using type 5 ribs keep in mind the following:

- The number of anchorages on the rib "i" must be equal to the number

of anchors on the right and left, even if they are not used (they can

be virtual, ie without lines)

- To define the Type 5 rib, use a number of lines equal to the number of anchors. Example:

1

5 5 1 1

1 60.0 60.0

80. 7.

2

5 5 2 1

1 60.0 60.0

80. 7.

3

5 5 3 1

1 60.0 60.0

80. 7.

4

5 5 4 1

1 60.0 60.0

80. 7.

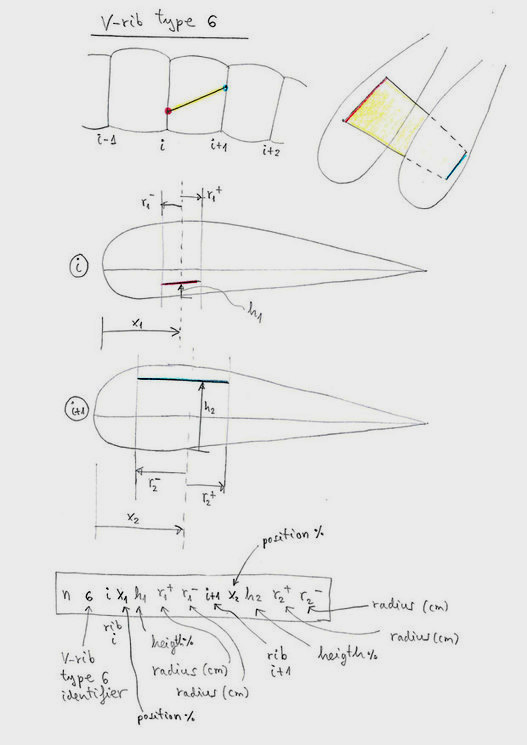

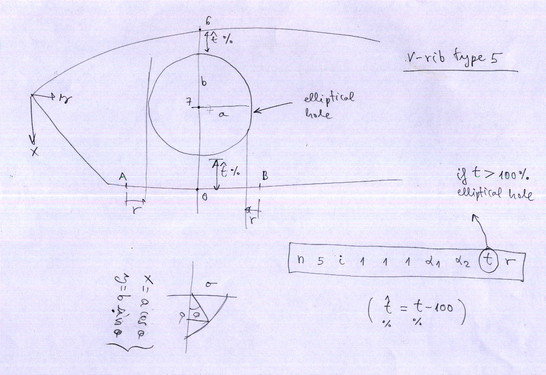

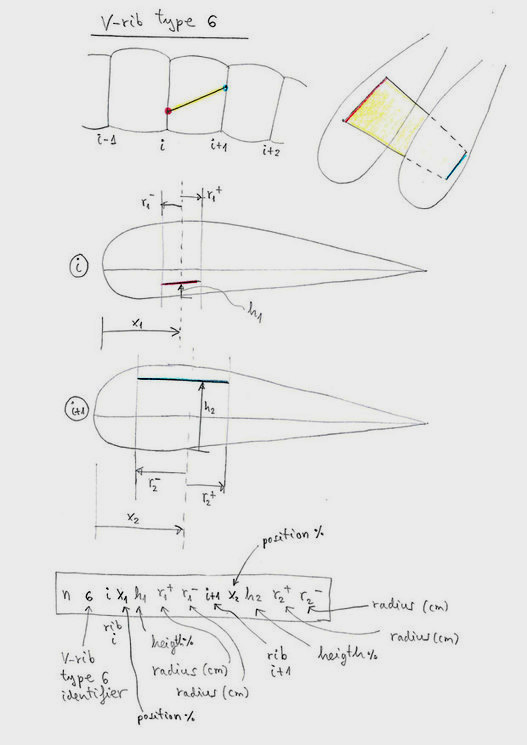

Type 6: general diagonal "VH-rib" between rib i and rib i+1

Type 6 is a general diagonal. It's very simple. A trapezoidal diagonal ranging from rib number i to rib number i+1. But the rib is totally configurable in size and position. It has been designed to develop competition paragliders CCC types, which need to jump between 4 and 5 cells without lines. But it can also serve to design simplest paragliders, and replacing some of the types of diagonals described above. It is also very useful to define transverse horizontal strips located in all parts of the wing (the tapes have not necessarily coincide with the anchor points).

Figure 24 V-rib type 6 general diagonal

Parameters:

n = number of V-rib (consecutive order)

6 = define V-rib "type 6"

i = number of initial rib

x1 = starting position as a percentage of the chord of the profile

h1 = initial height in percent of the local thickness profile

r1 = radius backwards (cm)

r1- = radius forward (cm)

i +1 = number of final rib

x2 = starting position as a percentage of the chord of the profile

h2 = initial height in percent of the local thickness profile

r2+ = radius backwards (cm)

r2- = radius forward (cm)

Type 6 uses 12 parameters, while the other V-ribs types, use only 10 parameters. This is no problem. The program can read the data file correctly. Simply, interpret the scheme. Try and see the results. Type-6 is now working and fully implemented.

Very important: The pieces "Type 6", must be defined consecutively, and line by line. With the following order: From the leading edge to the trailing edge, and from the center of the wing, to the wingtip. That is, first define all the pieces consecutively in rib number "i", before defining pieces in a rib greater than "i".

Ribs Types 11,12,13,14,15,16

Since version 3.14 of the program, six additional VH-rib types can be

used, named Type 11,12,13,14,15, and 16. Type 11 is the same as type 1, but absolute definitions of

lengths in cm, now are now set in % of the profile chord. The same for type

12 with respect to type 2, and so on until type 16, which is similar to

type 6. Types 11 and 1, 12 and 2, 13 and 3, 14 and 4, cannot be

combined in the same model. An auxiliary model can be made if

necessary.

When you enter the settings to the types 1,2,3,4,5,6, the absolute

lengths will be affected by the scaling factor of the wing (before this

does not happen). This allows you to scale the wings more uniformly.

Since version 3.14 the graphical presentation of the VH-ribs in 2D has

been greatly improved, and ensuring that the reference decimal numbers

are not shifted with respect to the pieces, as happened before.

The roman numbers fit much better and its size may be defined in

section 20.

Study examples, section 12 is very powerful and allows for almost any type of rib you can imagine. Example:

***************************************************

* 12. H V and VH ribs

***************************************************

24

> Use 24 VH-ribs

80

150

> X Y spacing

1

11 0 1 1

1 3.5

0

0

0

> VH-rib 1, Type 11

2

11 1 1 2

1 3.5

0

0 0

3

11 2 1 3

1 3.5

0

0 0

4

11 3 1 4

1 3.5

0

0 0

5

11 8 4 9

4 6.0

0

0 0

6

12 3 3 1

1 3.0 7.0

80.

90.

> VH-rib 6, Type 12

7

12 5 3 1

1 3.0 7.0

80. 90.

8

12 7 3 1

1 3.0 7.0

80. 90.

9

12 9 3 1

1 3.0 7.0

80. 90.

10

13 2 4 1

1 3.0 10.0

0.

0. > VH-rib 10, Type 13

11

13 4 4 1

1 3.0 10.0

0. 0.

12

13 6 4 1

1 3.0 10.0

0. 0.

13

14 2 2 1

1 3.0 7.0

80.

90. > VH-rib 13, Type 14

14

14 5 2 1

1 3.0 7.0

80. 90.

15

14 8 2 1

1 3.0 7.0

80. 90.

16

14 11 2 1

1 3.0 7.0

80. 90.

17

15 3 1 1

1 60. 50.

81.

2.0 > VH-rib 17 to 20, Type 15

18

15 3 2 1

1 60. 50.

81. 2.0

19

15 3 3 1

1 60. 50.

81. 2.0

20

15 3 4 1

1 60. 50.

81. 2.0

21

16 10 80.

10. 3. 3. 11

75. 85. 8. 8. > VH-rib 21, Type 16

22

16 11 75.

85. 8. 8. 12

75. 0. 3. 3.

23

16 6 18.

10. 3. 3. 7

18. 100. 5. 5.

24

16 7 18.

100. 5. 5.

8 18. 0. 3.

3.

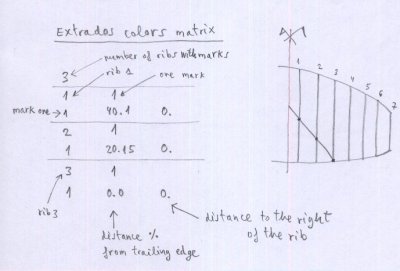

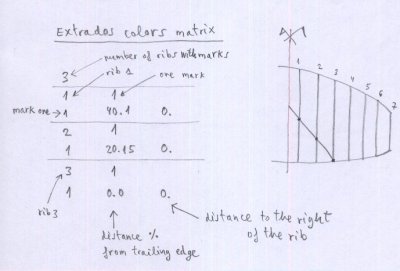

SECTION

15:

EXTRADOS COLORS

integer :

number of ribs with marks

integer,

integer : first rib number, number of marks

integer, real,

0. : first mark, distance % from TE, 0.

integer, real,

0. : second mark, distance % from TE, 0.

...

integer,

integer : second rib number, number of marks

integer, real,

0. : first mark, distance % from TE, 0.

integer, real,

0. : second mark, distance % from TE, 0.

...

and so on...

Figure

25. Extrados colors

New method (since lep-3.24) proposed by Pawel Lipsky (Altair Paragliders).

SECTION 15 Extrados colors and SECTION 16 Intrados colors

It is now possible to define color cuts according the method "2":

Write by lines:

integer

Write the NEGATIVE integer -2, thus the program uses case 2

integer

integer is the number of panels with colored cuts

Then, for each panel with color cuts, write two lines:

integer1 integer2

Where integer1 is the panel number, and integer2 the number of cuts in this panel

integer real1 real2 real3 real4

Where integer is the cut number, starting with 1

Where real1 is the cut to the left of the panel in % from the trailing edge

Where real2 is the cut to the right of the panel in % from the trailing edge

Where real3 is the width in mm of the seam edge to join colors

Where real4 is the number 0.0, unused fallback parameter

continue the same structure through the next cut, and then continue with the next panel

Example:

Panels 2,3,4 with cuts. 1 cut in panels 2 and 3 with 1 cut, panel 4 with 3 cuts.

*****************************************************

* 15. Extrados colors

*****************************************************

-2

3

2 1

1 40.1 20.15 10. 0.

3 1

1 20.15 0.00 10. 0.

4 3

1 0.0 15.0 10. 0.

2 15.0 30.0 10. 0.

3 50.0 60.0 10. 0.

Same definition to define the intrados cuts (section 16).

Note: When the wing has an odd number of panels (center panel of nonzero width),

the cut to the left of the center panel (panel 1) is defined exactly on the wing's axis of symmetry,

for make symmetrical designs possible.

SECTION

16:

INTRADOS COLORS

Like

extrados colors, works from version >= 2.41. For example, you may write the minimal

configuration:

1

1 1

1 0. 0.

SECTION

17:

ADITIONAL RIB POINTS

With this option,

auxiliary points can be

drawn in the ribs.

Typically to mark mylars,

or start and end points

of the nylon rods.

integer : number of points

real, real

: x-coordinate % of chord, y coordinate % of chord (first point)

....

real, real :

x-coordinate % of chord, y coordinate % of chord (last point)

SECTION

18:

ELASTIC LINES CORRECTION

Option to estimate the elastic elongation of the lines in

normal flight configuration.

These elongations are subtracted from strictly

geometric length, so that in flight, are the exact lengths of project. Option fully

functional but still under

development. To calculate the elongation, we take into

account the loads on each

line, and the rigidly coefficient of each line, the elongation estimated by Hook's law: F = k·dx

This load distribution is also used when calculating line branches, optimized according to option number 3 (SECTION 9).

real : load in

flight (kg)

real, real :

% load distribution in 2 lines rib

real, real, real

: % load distribution in 3 lines rib

real, real, real,

real : % load distribution in 4 lines rib

real, real, real, real, real : % load

distribution in 5 lines rib

integer, real,

real, real, real : p, d1, d2, d3 where

p = number of lines per rib (p 1 to 5)

d1 =

deformation in lower level with 10 kg

d2 =

deformation in medium level with 10 kg

d3 =

deformation in higher level with 10 kg

Example:

*****************************************************

* 18. Elastic lines corrections

*****************************************************

100

75

25

<<< A=75% B=25%

40

40

20

<<< A=40% B=40% C=20%

35 35 20 10 <<< A=35% B=35% C=20% D=10%

35 35 15 10 5 <<< A=35% B=35% C=15% D=10% E=5%

1 0.08 0.2 0.2

2 0.08 0.2 0.2

3 0.08 0.2 0.2

4 0.08 0.2 0.2

5 0.08 0.2 0.2

If

you are using version until 2.60 of leparagliding, you do not need to

continue typing, as it will not be considered. If you are using version

2.70 or higher, continue typing more settings.

SECTION

19: DXF LAYER NAMES

This section allows the user to choose some layers names in the DXF files. To facilitate the edition and modification of DXF files. In version 2.75 only the layers "points" "circles" and "triangles" are functional.

By lines, and regardless of the lines beginning with *

which are comments

or notes for help:

Line 1: integer

integer : max layers number, now is 10

Line 2: text1 text2

text1: general layer name (do not change this text)

text2: default layer name, to choose freely (with character and space restrictions)

Line 3: text1 text2

text1: line-external (do not change this text)

text2: layer name for external cuts, to choose freely (with character and space restrictions)

Line 4: text1 text2

text1: line-sewing (do not change this text)

text2: layer name for sewing lines, to choose freely (with character and space restrictions)

Line 4: text1 text2

text1: line-sewing (do not change this text)

text2: layer name for sewing lines, to choose freely (with character and space restrictions)

Line 5: text1 text2

text1: points (do not change this text)

text2: layer name for euclidean unidimensional points, to choose freely (with character and space restrictions)

Line 6: text1 text2

text1: circles (do not change this text)

text2: layer name for minicircle points, to choose freely (with character and space restrictions). Minicircles as alternative for points.

Line 7: text1 text2

text1: triangles (do not change this text)

text2: layer name for minitriangles, to choose freely (with character and space restrictions). Used is some special marks (tabs).

Line 8: text1 text2

text1: square (do not change this text)

text2: layer name for minisquares, to choose freely (with character and space restrictions). Used is some special marks.

Line 9: text1 text2

text1: text (do not change this text)

text2: text layer name, to choose freely (with character and space restrictions).

Line 10: text1 text2

text1: reference (do not change this text)

text2: reference layer name, to choose freely (with character and space restrictions).

Line 11: text1 text2

text1: notes (do not change this text)

text2: notes layer name, to choose freely (with character and space restrictions).

Example:

******************************************************

* 19. DXF layer names

******************************************************

10

general default

line-external cutexternal

line-sewing cutinternal

points points

circles circles

triangles triangle

square square

text text

reference refer

notes notes

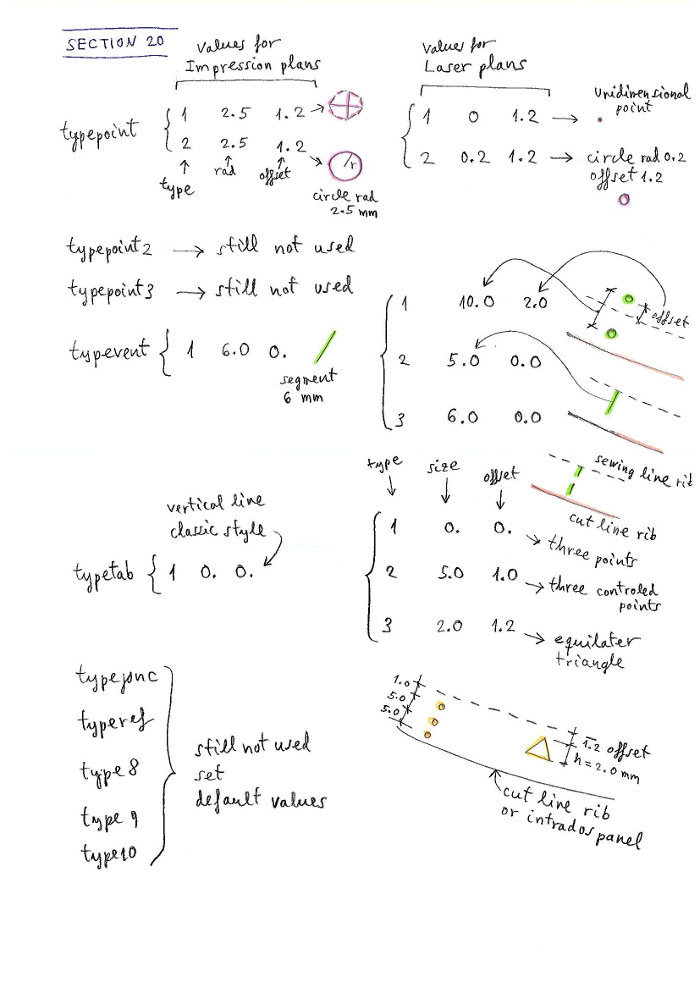

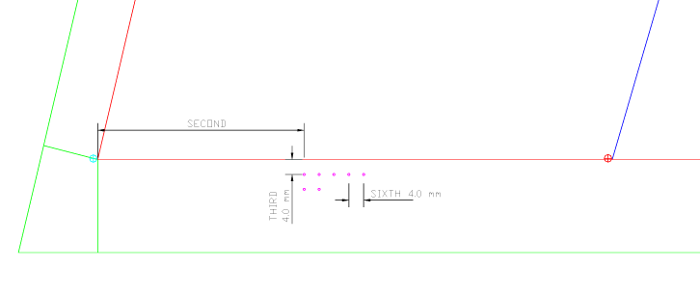

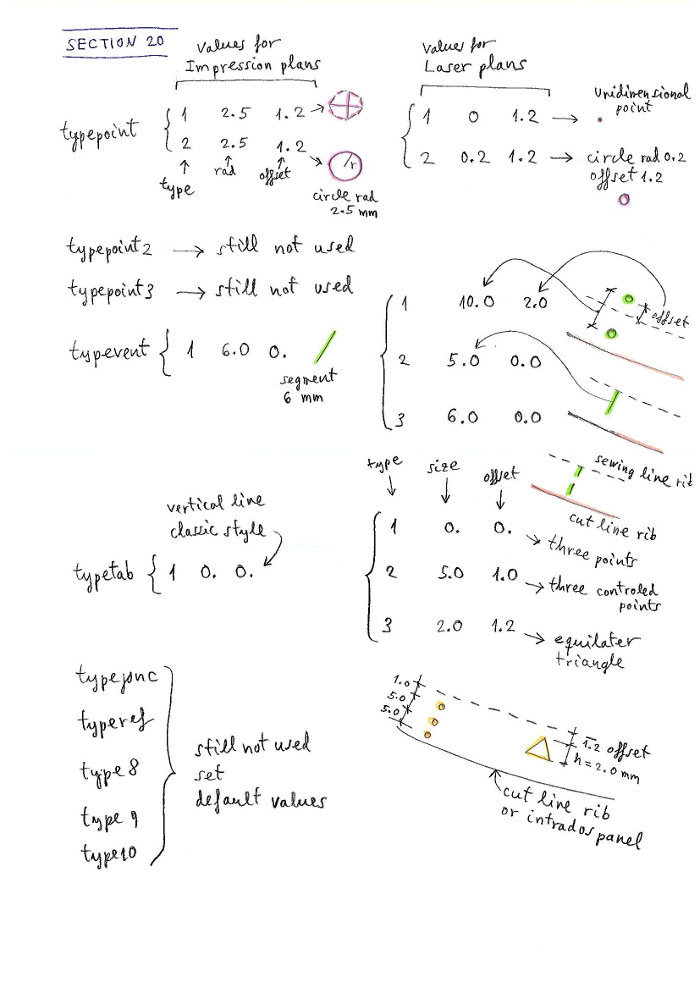

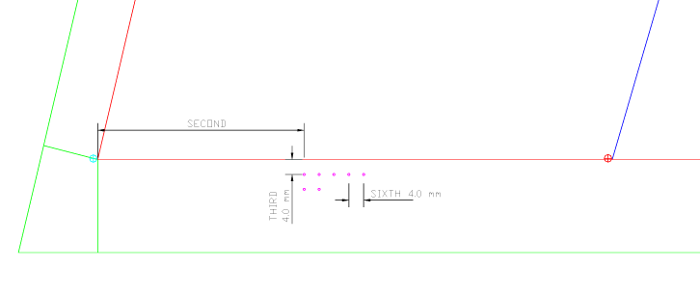

SECTION 20: MARKS TYPES

This section allows the user to choose different types of marking elements in DXF files (one-dimensional points, minicircles, triangles, segments, ...). This is especially useful for laser cutting plotters, and the ability to adapt marking to manufacturer preferences. Remember that

leparagliding generates two types of plans, some for use with

conventional printer ("print" version), and others for professional use with computerized

cutting plotters ("laser" version).

By lines, and regardless of the lines beginning with *

which are comments

or notes for help:

Line 1: integer

integer : max number of different marks, now is 10

Line 2: text integer real real integer real real (OK)

text: typepoint is the point for general use

integer: 1=constructed point, 2=minicircle - print

real: radius of minicircle in mm - print

real: offset in mm - print

integer: 1=unidimensional, 2=minicircle - laser

real: radius of minicircle in mm - laser

real: offset in mm - laser

Line 3: text integer real real integer real real (still not used, set defaults)

text: typepoint2

integer: 1=unidimensional, 2=minicircle - print

real: radius of minicircle in mm - print

real: offset in mm - print

integer: 1=unidimensional, 2=minicircle - laser

real: radius of minicircle in mm - laser

real: offset in mm - laser

Line 4: text integer real real integer real real (still not used, set defaults)

text: typepoint3

integer: 1=unidimensional, 2=minicircle - print

real: radius of minicircle in mm - print

real: offset in mm - print

integer: 1=unidimensional, 2=minicircle - laser

real: radius of minicircle in mm - laser

real: offset in mm - laser

Line 5: text integer real real integer real real (OK)

text: typevent

integer: 1=two green points, 2=segment, 3=double segment - print

real: points separation or segment in mm - print

real: offset in mm - print

integer: 1=two green points, 2=segment, 3=double segment - laser

real: points separation or segment in mm - laser

real: offset in mm - laser

Line 6: text integer real real integer real real (OK)

text: typetab

integer: 1=tree orange points, 2=tree orange full control, 3=triangle - print

real: points separation or segment in mm - print

real: offset in mm - print

integer: 1=tree orange points, 2=tree orange full control, 3=triangle - laser

real: points separation or triangle height in mm - laser

real: offset in mm - laser

Line 7: text integer real real integer real real (still not used, set defaults)

text: typejonc

integer: 1=single point, 2=segment, 3=double segment - print

real: points separation or segment in mm - print

real: offset in mm - print

integer: 1=single point, 2=segment, 3=double segment - laser

real: points separation or segment in mm - laser

real: offset in mm - laser

Line 8: text integer real real integer real real (still not used, set defaults)

text: typeref

integer: 1,2,3 - print

real: dimesion in mm - print

real: offset in mm - print

integer: 1,2,3 - laser

real: dimension in mm - laser

real: offset in mm - laser

Line 9: text integer real real integer real real (OK)

text: type8 - romano numbering in panels generated using section 29

integer: 1 not used

real: 0.2 spanning

from 0.0 to 1.0 means the position of the roman number (0.0 totally

to the left and 1.0 totally to the right, normal values 0.2 or 0.5 - print and laser

real: 4.0 means the

vertical offset in mm with respect to the baseline. May be

positive or negative number - print and laser

integer: 1 not used

real: 0.0 not used

real: 4.4 means the offset in mm between dots of the roman

numeral (global size of the roman numerals) - print and laser

Line 10: text integer real real integer real real (OK)

text: type9 - general numbers size, and roman marks size in ribs,

integer: 1 not used

real: 0.0 not used

real: 7.0 decimal integer numbers size in cm, in leading edge, ribs, trailing edge panels

integer: 1 not used

real: 3.3 means the offset in mm between dots of the roman

numeral (global size of the roman numerals) in rod pockets. If set to 0.0 then roman is not drawn

real: 4.5 means the offset in mm between dots of the roman

numeral (global size of the roman numerals) in ribs - print and laser

Line 11: text integer real real integer real real (OK)

text: type10 - general numbers size in VH-ribs, and roman marks size in VH-ribs,

integer: 1 not used

real: 0.0 not used

real: 6.0 decimal integer numbers size in cm, in VH-ribs

integer: 1 not used

real: 0.0 not used

real: 4.5 means the offset in mm between dots of the roman

numeral (global size of the roman numerals in VH-ribs) - laser

Figure 26a. Section 20 reference marks. Types 1,2,3,4,5,8,9,10 now fully functional.

Figure 26b. Type8 marks parameters interpretation

Check that the

parameters you use are correct, otherwise the size of the Roman

numerals or decimals will not be appropriate. Since version 3.14 is

VERY recommended to use this (or similar) example invariant bloc:

******************************************************

* 20. Marks types

******************************************************

10

typepoint 1 0.25 1.2 2 0.3 1.2

typepoint2 1 0.25 1.2 2 0.2 1.2

typepoint3 1 0.25 1.2 2 0.2 1.2

typevent 1 10. 0.0 2 2.0 0.0

typetab 1 10. 0.0 3 2.0 0.0

typejonc 1 10. 0.0 2 2.0 0.0

typeref 1 5.0 1. 1 2.0 0.0

type8 1 0.2 5.0 1 0.0 5.0

type9 1 0.0 7.0 1 3.2 4.5

type10 1 0.0 6.0 1 0.0 3.33

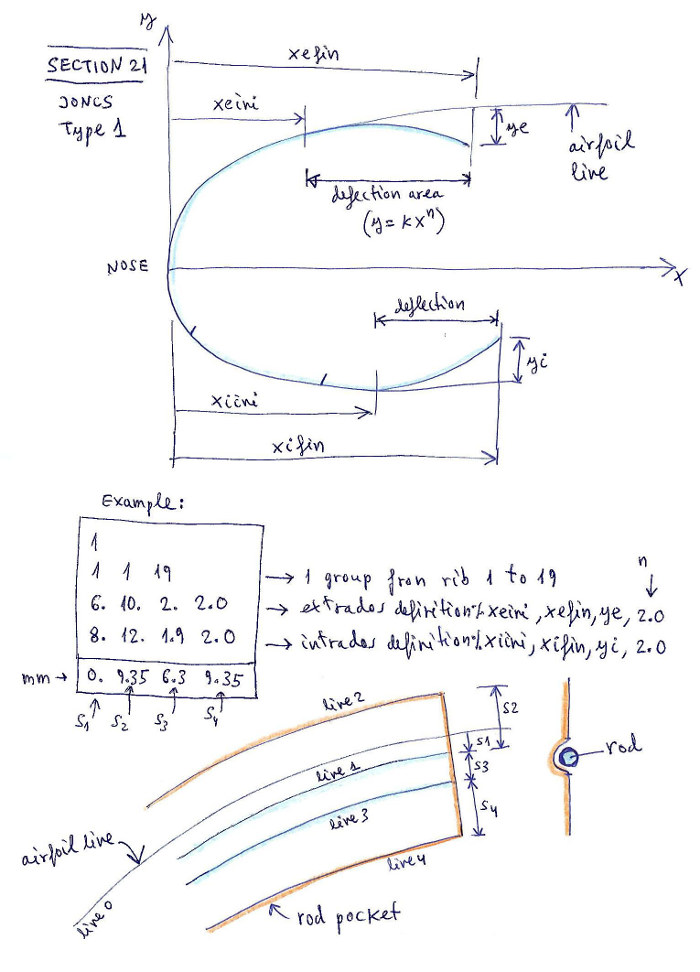

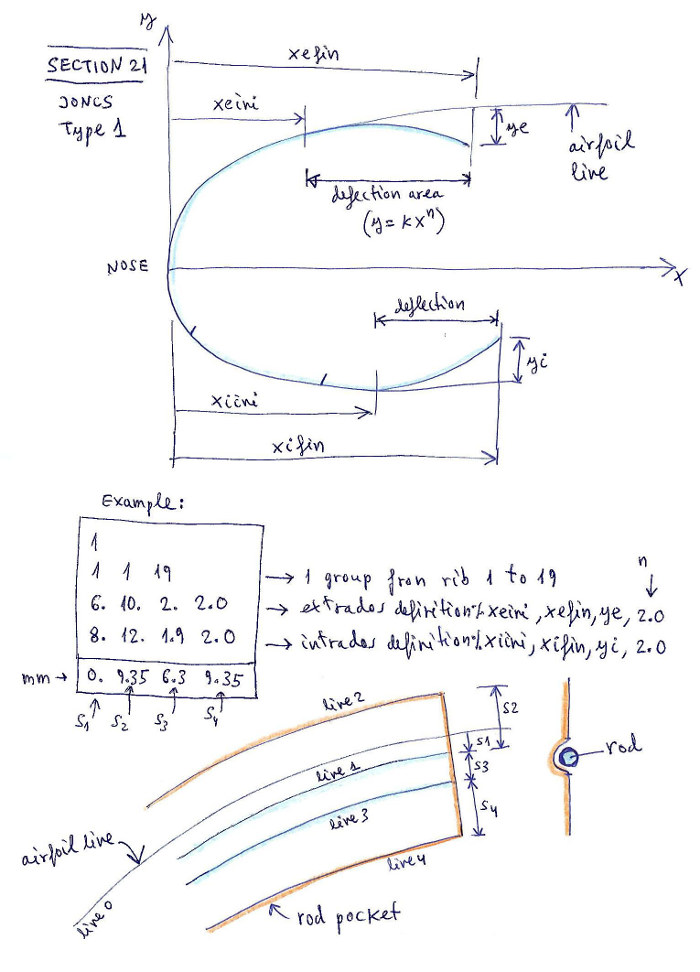

SECTION 21: JONCS DEFINITION (NYLON RODS)

Section

is fully functional. Now it is possible to define type 1 and type 2

rods, which

are the most used. Type "1" is rod on the nose with small

deflections at both

ends, which are completely controllable in position, transition, and

depth of deflection, with 8 parameters. Type "2" is straight or arched

rod defined to any position within the profile, which can be at any

position within the profile, defined by coordinates. The structure of

the section is a bit complex, but it has its own logic. The program calculates the rods

and shapes of the pockets, which are also fully controllable in widths,

with 4 parameters. It is possible to define different rods for each

cell, individually or by groups. If

you don't need rods, leave the value to "0". In this section we will

use the following basic concepts: scheme, bloc (of data), type (of

rod), group (of ribs).

The first number in the section is an integer, which we called the "scheme".

The scheme "0" means, not defining any rod. And here ends the section. Easy!

Line 1: integer

if integer = 0 rods are not considered

Example 1: Scheme "0" means do not use rods

*******************************************************

* 21. JONCS DEFINITION (NYLON RODS)

*******************************************************

0

The scheme "1" means use rods

type "1" in the nose. At the bottom line write the number of groups.

Then write each group consecutively using four lines. This is the

detailed structure of the scheme 1:

Line 1: integer

if integer = 0 rods are not considered

if integer = 1 add some others parametes to define and draw rods

Only if first integer is 1 (use joncs "type 1") then add:

Line 2: integer

integer: number of groups to define

Line 3: integer1 integer2 integer3

integer1: 1 (group number 1)

integer2: number of first rib in group 1

integer3: number of last rib in group 1

Line 4: real1 real2 real3 real4

real1: extrados init point deflection in % of chord

real2: extrados final point deflection in % of chord

real3: value of max deflection in intrados % of chord

real4: value n of exponent in curve of deflection type y=k·x^n (normaly use n=2.0, parabolic)

Line 5: real1 real2 real3 real4

real1: intrados init point deflection in % of chord

real2: intrados final point deflection in % of chord

real3: value of max deflection in intrados % of chord

real4: value n of exponent in curve of deflection type y=k·x^n (normaly use n=2.0, parabolic)

Line 6: real1 real2 real3 real4

real1: line 1, offset (mm) defining the rod (see figure)

real2: line 2, external width of pocket (mm)

real3: line 3, width for rod between sewing lines (mm)

real4: line 4, internal width of pocket (mm)

Lines 7,8,9,10 repeat same definitions for the group 2, and so on until final group.

Note that it is possible to define as many groups as profiles have the wing, and thus define a different rod for each profile. But normally with a group or two it is sufficient for the whole wing.

Example 2: Scheme "1". Using two groups. Group 1 from rib 1 to 15, and group 2 from rib 16 to 19

*******************************************************

* 21. JONCS DEFINITION (NYLON RODS)

*******************************************************

1

2

1 1 15

5.5 10. 1.5 2.0

5. 11. 2.2 2.0

0.0 9.35 6.3 9.35

2 16 19

5. 9. 2.5 2.0

5. 12 3. 2.0

0.0 9.35 6.3 9.35

Figure 27a. Section 21 joncs type 1 used in scheme "1"

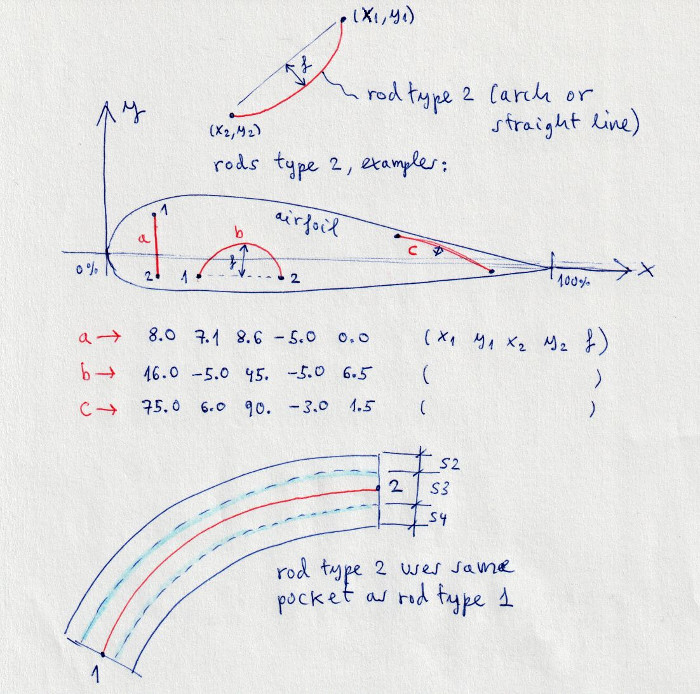

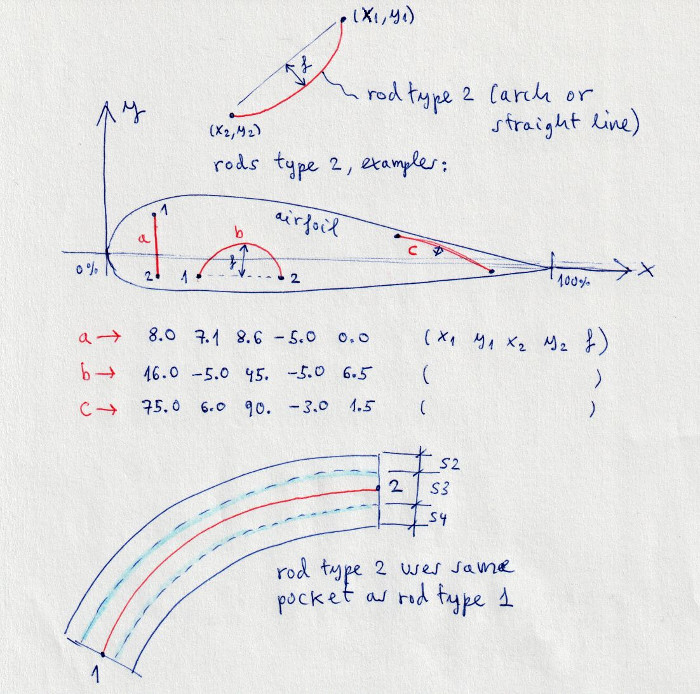

The scheme "2":

Starting from version 3.12 of the program, the definition can be

extended... :-) Now it is possible to define a more general model,

called "scheme 2". In the scheme 2, we can add rods type "1" and many

(not limited) rods type "2 " within the profile. Type 2 are

arc-shaped or straight-line rods. If deemed necessary, other types may

be added later.

The structure is as follows:

Line 1: integer

integer: 2 means use scheme "2"

Line 2: integer

integer: number of data blocs to define

Line 3: integer1 integer2

integer1: number of data bloc, starting with 1 and increasing by 1 the subsequent bloc

integer2: rod type can be 1 or 2

Line 4: integer

integer: number of groups to define

If integer2 in line3 was 1, then write consecutively the four lines

that define the geometry of the rods type 1 (lines 3,4,5,6 from scheme

1) and continue with more four lines for next group.

If integer2 in line3 was 2, then write consecutively the tree lines that define the geometry of the rods type 2:

Figure 27b. Rods type 2 (arch or straight line)

Line 5: integer1 integer2 integer3

integer1: 1 (group number 1)

integer2: number of first rib in group 1

integer3: number of last rib in group 1

Line 6: real1 real2 real3 real4 real5

real1: x-coordinate of rod starting at point 1 (x1,y1) in % of airfoil chord

real2: y-coordinate of rod starting at point 1 (x1,y1) in % of airfoil chord

real3: x-coordinate of rod ending at point 2 (x2,y2) in % of airfoil chord

real4: y-coordinate of rod ending at point 2 (x2,y2) in % of airfoil chord

real5: max deflection of the arc in % of airfoil chord. If 0.0 draws a straight line

Line 7: real1 real2 real3 real4

real1: line 1, offset not used and put 0.0 value

real2: line 2, external width of pocket (mm)

real3: line 3, width for rod between sewing lines (mm)

real4: line 4, internal width of pocket (mm)

Continue with next group...

Continue with next bloc of data...

This definition may seem complicated (and it is!) but is understood better with examples and doing tests and seeing the results

Example

3: Comented scheme "2". Using only one data bloc type 2 and two group.

Group 1 from rib 1 to 15, and group 2 from rib 16 to 19

*******************************************************

* 21. JONCS DEFINITION (NYLON RODS)

*******************************************************

2 < scheme 2

1

< only one bloc

1

2

< bloc 1 uses rods type 2

2

< bloc 1 uses two groups

1 1 15 < group 1 from rib 1 to 15

20. 2. 30. -2.0 3.0 < coordinates (x1,y1) (x2,y2) and deflection all in % of chord

0.0 9.35 6.3 9.35 < rod pocket sizes in mm

2 16 20 < group 2 from rib 16 to 20

40. 4. 30. -3.2 0.0 < coordinates (x1,y1) (x2,y2) and deflection all in % of chord

0.0 9.35 6.3 9.35 < rod pocket sizes in mm

Example 4: Comented scheme "2". Using two data blocs and two groups in each bloc.

*******************************************************

* 21. JONCS DEFINITION (NYLON RODS)

*******************************************************

2 < scheme 2

2

< use two blocs

1 1

< first bloc uses rods type 1

2

< first bloc uses two groups

1 1 15 < group 1 from rib 1 to 15

5.5 10. 1.5 2.0

5. 11. 2.2 2.0

0.0 9.35 6.3 9.35

2 16 19 < group 2 from rib 16 to 20

5. 9. 2.5 2.0

5. 12 3. 2.0

0.0 9.35 6.3 9.35

2

2

< second bloc uses rods type 2

2

< second bloc uses two groups

1 1 15 < group 1 from rib 1 to 15

20. 2. 30. -2.0 3.0 < coordinates (x1,y1) (x2,y2) and deflection all in % of chord

0.0 9.35 6.3 9.35 < rod pocket sizes in mm

2 16 20 < group 2 from rib 16 to 20

40. 4. 30. -3.2 0.0 < coordinates (x1,y1) (x2,y2) and deflection all in % of chord

0.0 9.35 6.3 9.35 < rod pocket sizes in mm

Number of data blocs limited to 20, and number of groups to 100, then a lot of rods in each airfoil!

Test and see the results!

Figure 27c. Rods type 1 (nose reinforcement) and type 2 (arch or straight line)

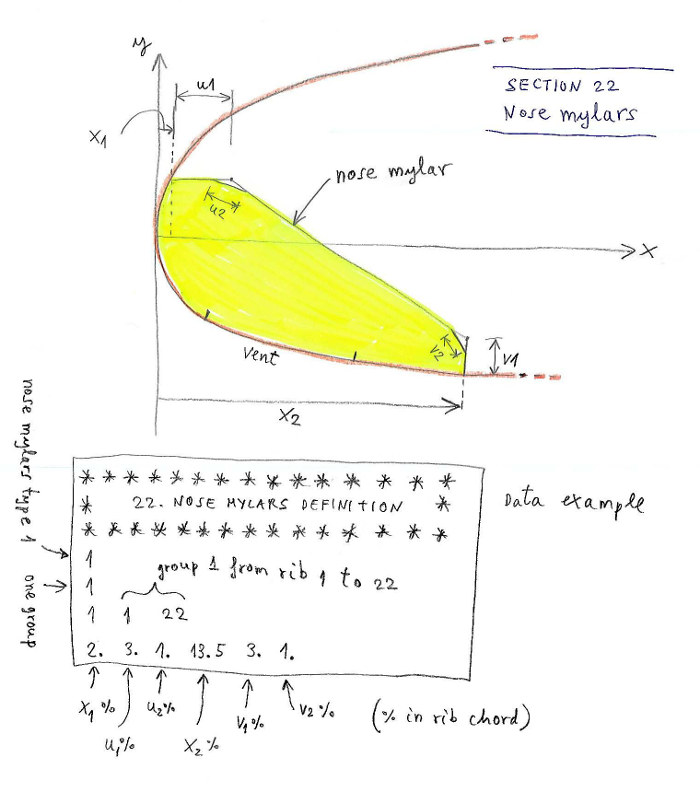

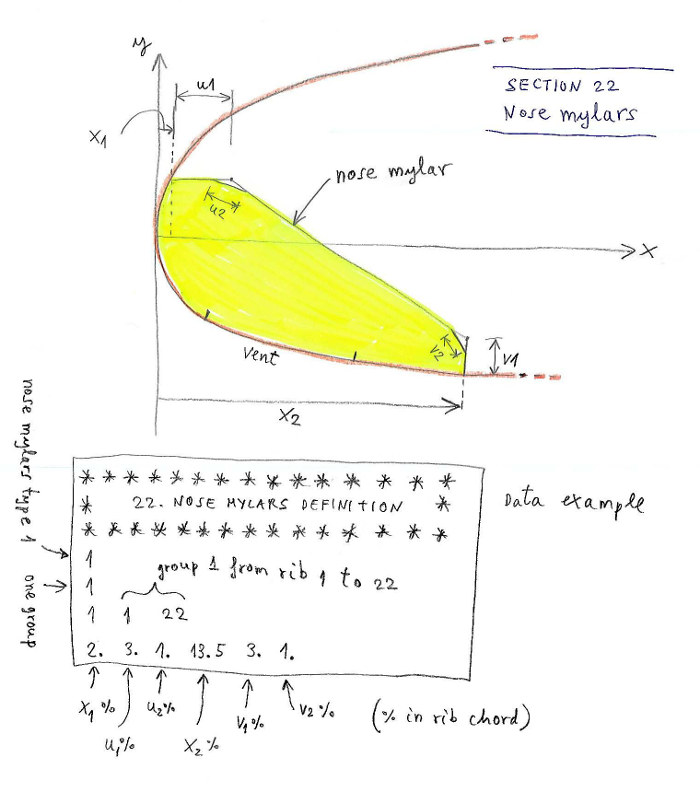

SECTION 22: NOSE MYLARS DEFINITION

This section allows the user to draw nose mylars.

Line 1: integer

if integer = 0 mylars are not considered

if integer = 1 add some others parametes to define and draw mylars

Example 1:

*******************************************************

* 22. NOSE MYLARS DEFINITION

*******************************************************

0

Example 2:

*******************************************************

* 22. NOSE MYLARS DEFINITION

*******************************************************

1

1

1 1 22

2. 3.0 1.0 13.5 3. 1.

Figure 28. Section 22 nose mylars definition

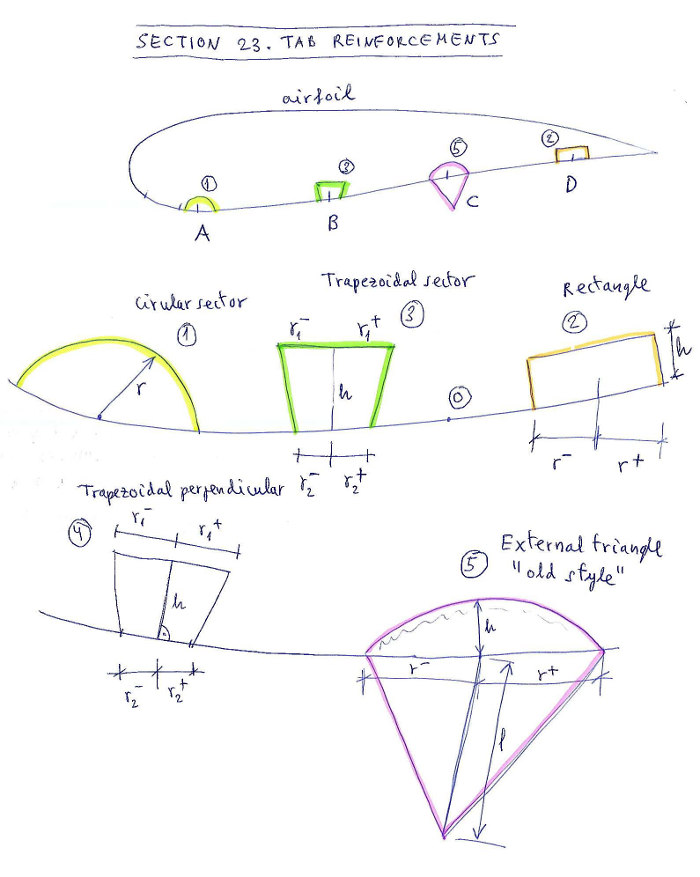

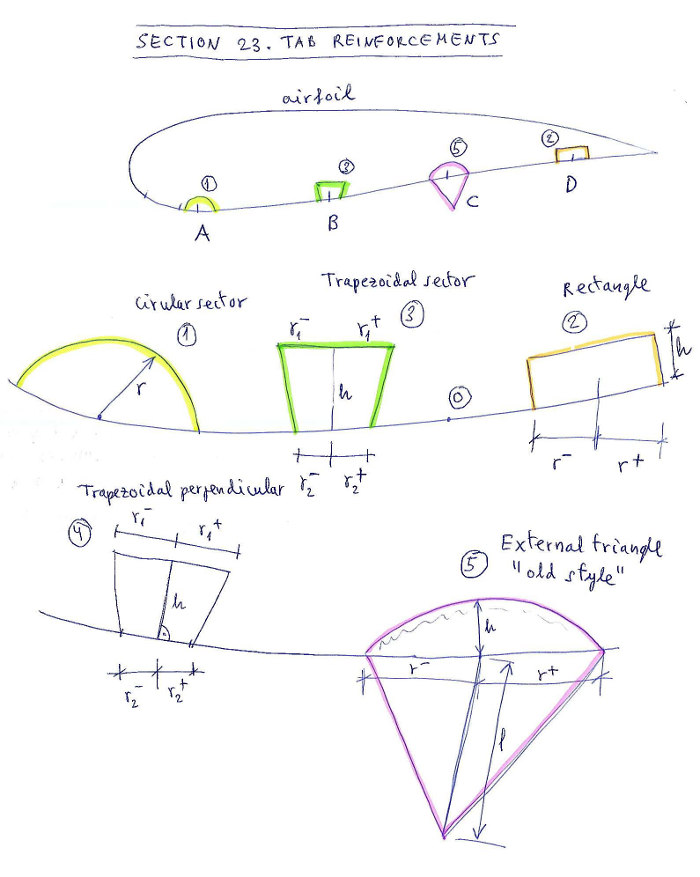

SECTION 23: TAB REINFORCEMENTS

This section allows the user to draw tab reinforcements. Still not functional. Leave the value to "0".

Line 1: integer

if integer = 0 tab reinforcements are not considered

if integer = 1 add some others parametes to define and tab reinforcements

Example 1:

*******************************************************

* 23. TAB REINFORCEMENTS

*******************************************************

0

Example 2:

*******************************************************

* 23. TAB REINFORCEMENTS

*******************************************************

1

1

1 1 22

2 2 1 5 3

schemes

1 0 p1 p2 p3 p4 p5

2 0 p1 p2 p3 p4 p5

3 0 p1 p2 p3 p4 p5

4 1 p1 p2 p3 p4 p5

5 1 p1 p2 p3 p4 p5

In

this data, one group of reinforcements applicable to ribs 1 to 22 is

defined. On the tabs A B C D E, the "schemes" 2,2,1,5,3 respectively are

applied. The schemes are defined below the word "schemes":

- Scheme 1 (circular sector), parameter "0" means use

units in % of chord, and 5 parameters to define the tab. In this case

only the radius r.

- Scheme 2 (trapezoidal sector), parameter "0" means use units in

% of chord, and 5 parameters to define the tab. In this case r1-,r1+,r2-,r2+,h.

- Scheme 3 (circular sector), parameter "0" means use units in

% of chord, and 5 parameters to define the tab. In this case only r-,r+,h,l. The shape of the triangle is calculated automatically taking into account the inclination of the line in space. The length "l" is discounted at the final length of the line.

-

Scheme 4 (rectangular sector), parameter "1" means

use absolute units in cm, and 5 parameters to define the tab. In this

case only r-,r+,h.

- Scheme 5 (circular-triangular sector), parameter "1" means

use absolute units in cm, and 5 parameters to define the tab. In this

case only r-,r+,h,l.

Figure 29. Section 23 tab reinforcements

Another example, with two groups, group 1 from ribs 1 to 10, group 2 from 11 to 22. Group 2 uses scheme "1" for all tabs:

*******************************************************

* 23. TAB REINFORCEMENTS

*******************************************************

1

2

1 1 10

2 2 1 5 3

2 11 22

1 1 1 1 1

schemes

1 0 p1 p2 p3 p4 p5

2 0 p1 p2 p3 p4 p5

3 0 p1 p2 p3 p4 p5

4 0 p1 p2 p3 p4 p5

5 1 p1 p2 p3 p4 p5

SECTION 24: GENERAL 2D DXF OPTIONS

This section allows the user to define some colors in the 2D DXF plans.

Line 1: integer

if integer = 0 DXF options set by default

if integer = 1 add some others parameters for DXF

Only if first integer is 1 then add:

Line 2: text1 integer text2

tex1: A_lines_color (do not change this text)

integer: color number index for "A" lines

text2: color name (optional text not used)

Line 3: text1 integer text2

tex1: B_lines_color (do not change this text)

integer: color number index for "B" lines

text2: color name (optional text not used)

Line 4: text1 integer text2

tex1: C_lines_color (do not change this text)

integer: color number index for "C" lines

text2: color name (optional text not used)

Line 5: text1 integer text2

tex1: D_lines_color (do not change this text)

integer: color number index for "D" lines

text2: color name (optional text not used)

Line 6: text1 integer text2

tex1: E_lines_color (do not change this text)

integer: color number index for "E" lines

text2: color name (optional text not used)

Line 7: text1 integer text2

tex1: F_lines_color (do not change this text)

integer: color number index for "F" brake lines

text2: color name (optional text not used)

Example:

*******************************************************

* 24. GENERAL 2D DXF OPTIONS

*******************************************************

1

A_lines_color 1 red

B_lines_color 30 orange

C_lines_color 3 green

D_lines_color 4 cyan

E_lines_color 6 magenta

F_lines_color 5 blue

Note: Remember usual color index numbers for CAD systems:

1= red, 2=yellow, 3=green, 4=cyan, 5=blue, 6=magenta 7=white 8=dark grey 9= grey,... up to 255 depending on your color palette. It is preferable not to use colors with more than two digits.

SECTION 25: GENERAL 3D DXF OPTIONS

This section allows the user to define some colors in the 3D DXF plans. Allows to draw unifilar not ovalized versions of the surfaces.

Line 1: integer

if integer = 0 DXF options set by default

if integer = 1 add some others parameters for the 3D DXF

Only if first integer is 1 then add:

Line 2: text1 integer text2

tex1: A_lines_color (do not change this text)

integer: color number index for "A" lines

text2: color name (optional text not used)

Line 3: text1 integer text2

tex1: B_lines_color (do not change this text)

integer: color number index for "B" lines

text2: color name (optional text not used)

Line 4: text1 integer text2

tex1: C_lines_color (do not change this text)

integer: color number index for "C" lines

text2: color name (optional text not used)

Line 5: text1 integer text2

tex1: D_lines_color (do not change this text)

integer: color number index for "D" lines

text2: color name (optional text not used)

Line 6: text1 integer text2

tex1: E_lines_color (do not change this text)

integer: color number index for "E" lines

text2: color name (optional text not used)

Line 7: text1 integer text2

tex1: F_lines_color (do not change this text)

integer: color number index for "F" brake lines

text2: color name (optional text not used)

Line 8: text1 integer integer text2

tex1: Extrados (do not change this text)

integer: if set to "0" unifiilar extrados is not drawn, if set to "1" is drawn

integer: color index for the extrados

text 2: optional text with the color name

Line 9: text1 integer integer text2

tex1: Vents (do not change this text)

integer: if set to "0" unifiilar vents is not drawn, if set to "1" is drawn

integer: color index for the vents

text 2: optional text with the color name

Line 10: text1 integer integer text2

tex1: Intrados (do not change this text)

integer: if set to "0" unifiilar intrados is not drawn, if set to "1" is drawn

integer: color index for the intrados

text 2: optional text with the color name

Example:

*******************************************************

* 25. GENERAL 3D DXF OPTIONS

*******************************************************

1

A_lines_color 1 red

B_lines_color 8 grey

C_lines_color 8 grey

D_lines_color 8 grey

E_lines_color 8 grey

F_lines_color 30 orange

Extrados 1 5 blue

Vents 0 1 red

Intrados 1 3 green

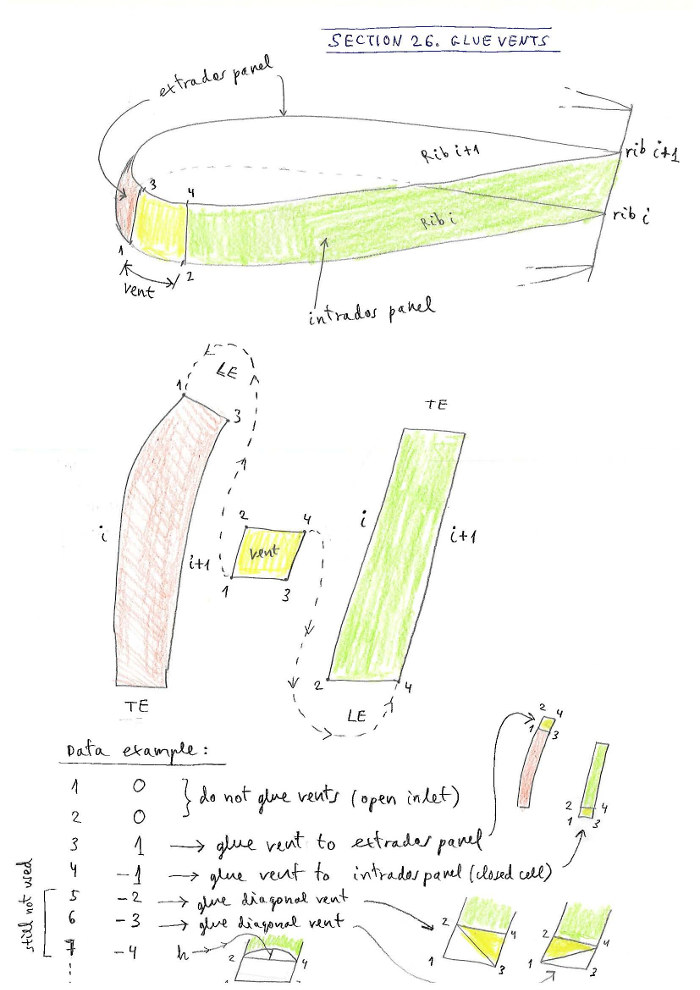

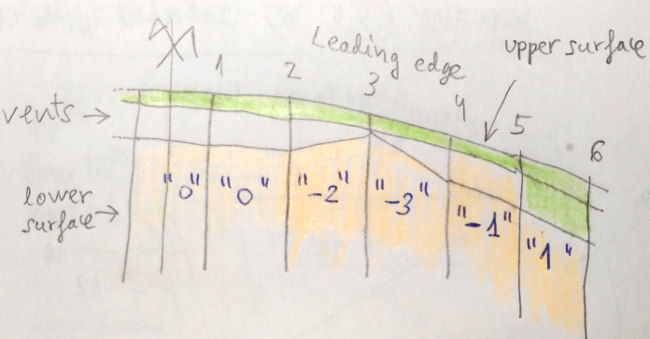

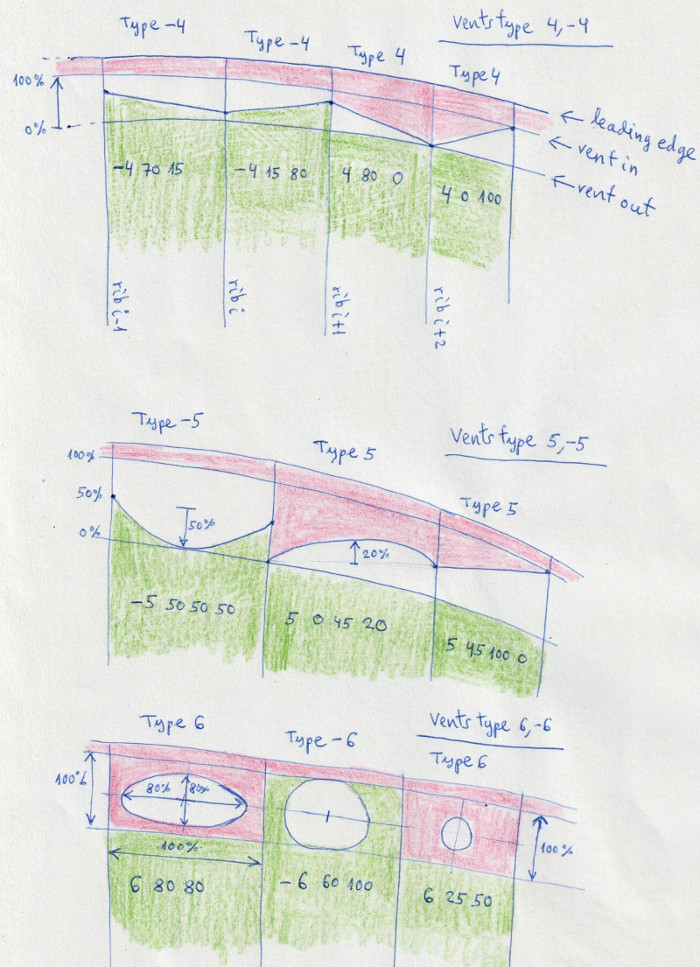

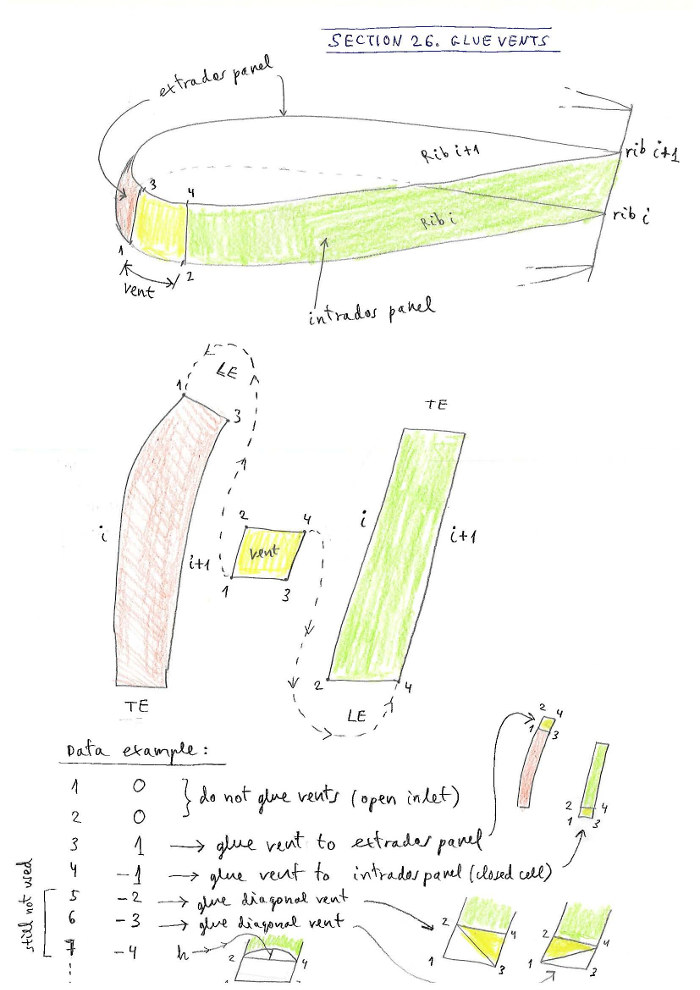

SECTION 26. GLUE VENTS

This

section allows us to define different types of air inlets (vents),

and automatically "glue" into the panel of extrados, intrados, or

to separate them.

The vents include sewing edges. The skin tension in the vent is linear

and automatically corresponds to that defined at the points

corresponding in extrados and intrados.

The vent definition is very easy and intuitive. A

row is defined for each rib. The first number is the rib number, the

next is the vent type, and then zero, two, or three parameters,

depending on the type.

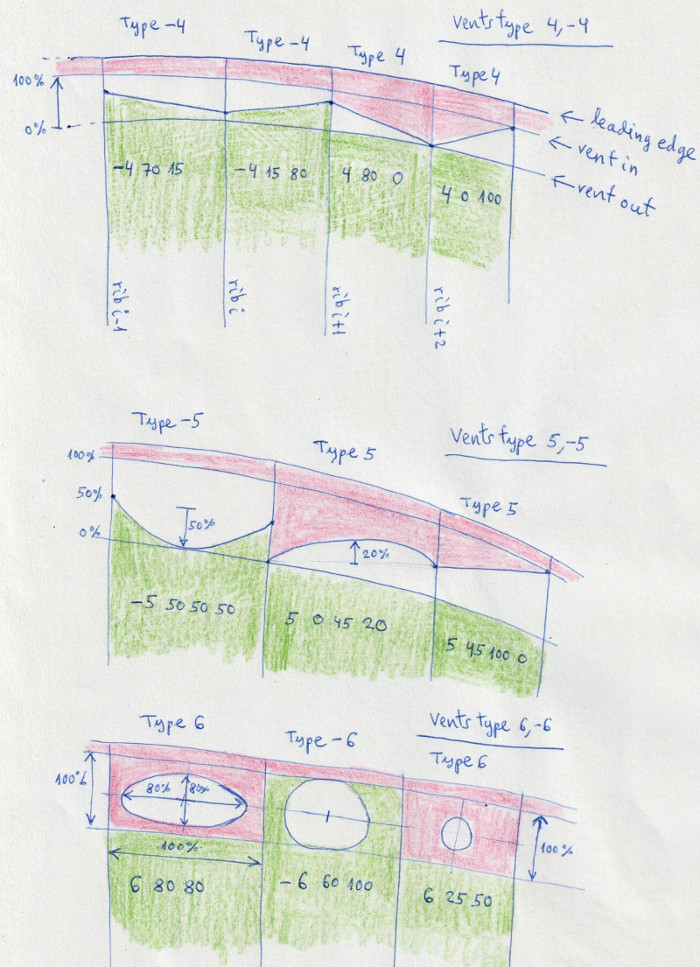

Available vent types (version lep-3.17) 0,1,-1,-2,-3,4,-4,5,-5,6,-6:

0 means do not glue anywhere (open air inlet).

1 means glue the vent to the extrados (normally used in paragliders single skin type)

-1 means glue the vent to the intrados (usually means, closed cell)

-2 means diagonal vent 100% open ant left, glued to intrados

-3 means diagonal vent 100% open alt right, glued to intrados

-4 50 30 mean general diagonal vent 50% closed at left and 30% closed at right, glued to intrados

4 0 80 mean general diagonal vent 0% open at left and 80% open at right, glued to extrados

5 50 100 10 mean arched vent, 50% open at left, 100% open at right, and 10% arc depth, glued to intrados

-5 50 40 15 mean arched vent, 50% closed at left, 40% closed at right, and 15% arc depth, glued to intrados

6 80 80 means elliptical inlet, width of 80% in X direction and 80% in Y direction, glued to extrados

-6 50 85 means elliptical inlet, width of 50% in X direction and 85% in Y direction, glued to intrados

Section 26 structure:

Line 1: integer

if integer = 0 then end the section and use old vents style (not recommended)

if integer = 1 add some others parameters for precise vents control

Only if first integer is 1 then add N lines, one for each airfoil number i:

Line i: integer1 integer2 real1 real2 real3

integer1: airfoil number (cell between airfoil i and airfoil i-1)

integer2: vent parameter (available parameters 0,1, -1,-2,-3,4,-4,5,-5,6,-6 as explained above)

real1: parameter 1 (0 to 100). Start point at left (vents 4,-4,5,-5), or horizontal axis in 6,-6

real2: parameter 2 (0 to 100). Start point at right (vents 4,-4,5,-5), or vertical axis in 6,-6

real3: parameter 3 (0 to 100). Arch depth in vents type 5 or -5

Examples 1 (use old style, not recommended):

*******************************************************

* 26. GLUE VENTS

*******************************************************

0

Examples 2 (full vent control):

*******************************************************

* 26. GLUE VENTS

*******************************************************

1

1 0

2 0

3 1

4 -2

5 -3

...

20 -2

21 -1

22 -1

23 -1

Examples 3 (advanced vents):

*******************************************************

* 26. GLUE VENTS

*******************************************************

1

1 0

2 0

3 1

4 -4 100. 0. ---> general diagonal vent from 100% to 0%

5 -4 10. 50. ---> general diagonal vent from 10% to 50%

...

19 -5 0. 0. 15 ---> arc vent 15% depth

20 -6 80 80 ---> elliptical inlet

21 -1

22 -1

23 -1

Figure 30. Glue vents

Figure 31: Vents types 0,1,-1,-2,-3

Figure 31b: Vents types -4,4 (general diagonal) -5,5 (general arc) -6,6 (elliptical inlet), available in lep-3.17 and later.

Note that type 4 also includes cases 0,1,2,3, and type -4 cases 0, -1,

-2, -3. Finally type 5 includes case 4, and -5 includes case -4.

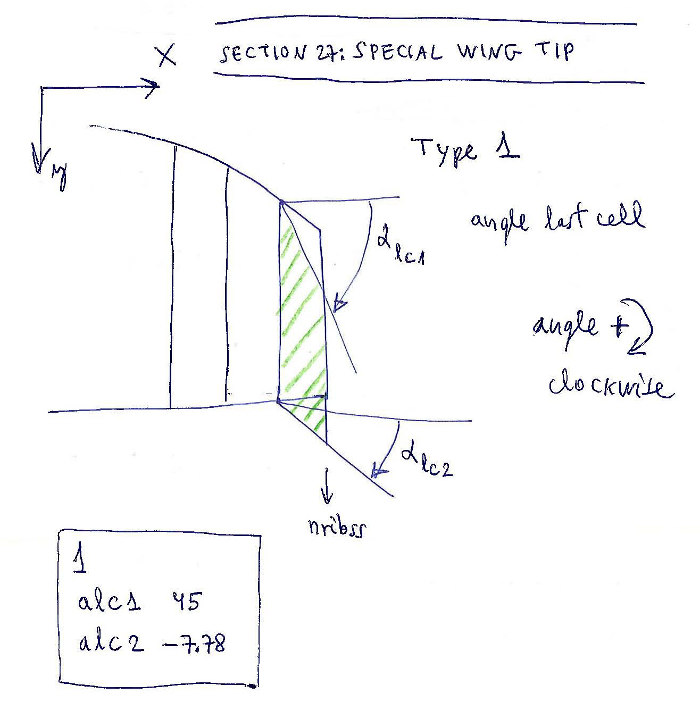

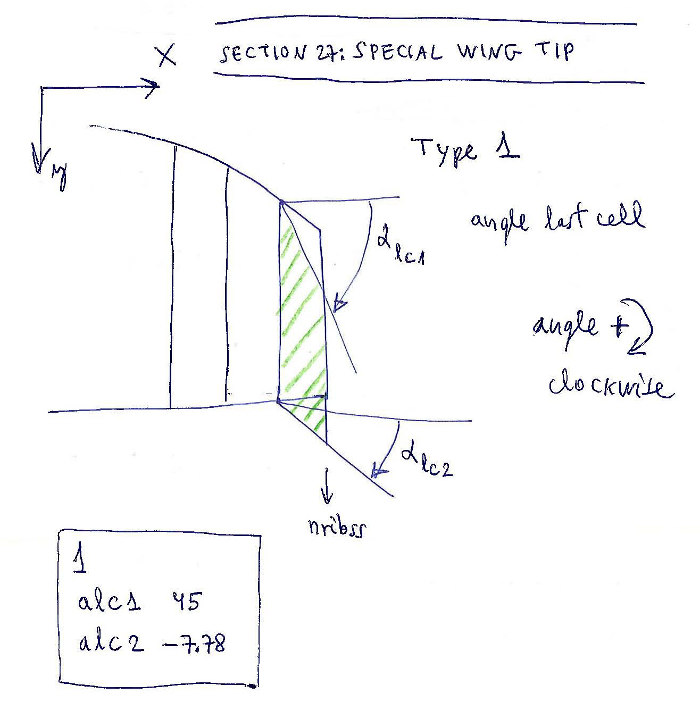

SECTION 27 SPECIAL WINGTIPS

It is used for defining wingtips with special shapes:

Figure 32. Special wingtip

Line 1: integer

if integer = 0 do not add wingtip modifications(set by default)

if integer = 1 add some wingtip modifications

Only if first integer is 1 then add:

Line 2: text real

text: AngleLE (do not change this text)

real: angle in degrees between the horizontal and the leading edge in the last cell

Line 3: text real

text: AngleTE (do not change this text)

real: angle in degrees between the horizontal and the trailing edge in the last cell

Example 1:

*******************************************************

* 27. SPECIAL WING TIP

*******************************************************

1

AngleLE 45

AngleTE -7.78

"1" refers to define "type 1" wing tip modifications. It is planned to define several modifications. Type 1 is the simplest.

"AngleLE" is a

name not computed. It serves to remember that next we have to write the

new angle in degrees between the horizontal and the leading edge in the

last cell. It is usual to force the angle of the last cell, and this

section allows it to be done without modifying the geometry matrix. Set

45º for example. "AngleTE" is a name not computed for the trailing edge. Set the angle as desired, -7.78º for example.

Example 2:

*******************************************************

* 27. SPECIAL WING TIP

*******************************************************

0

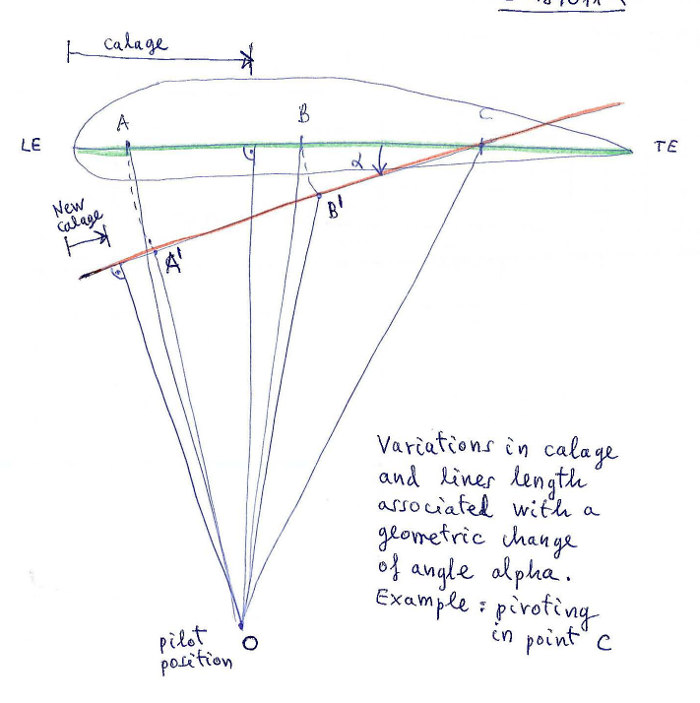

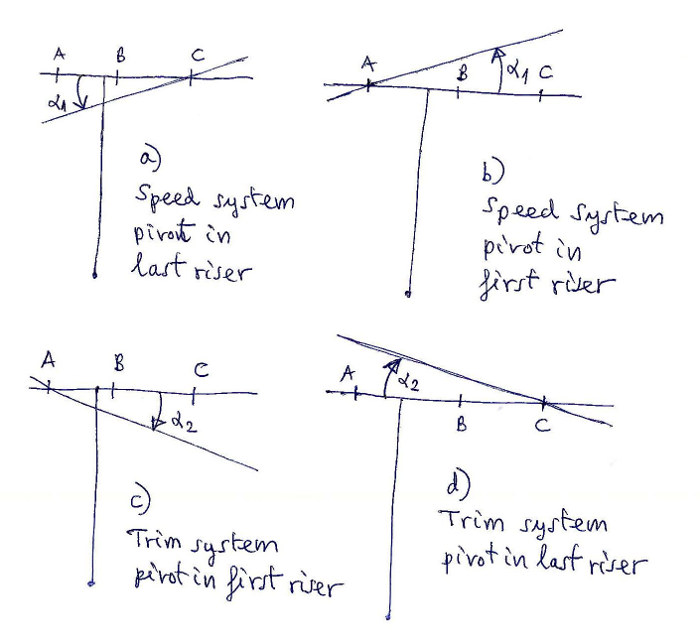

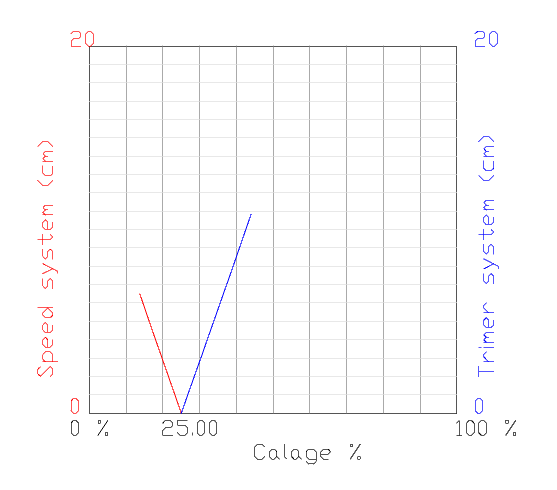

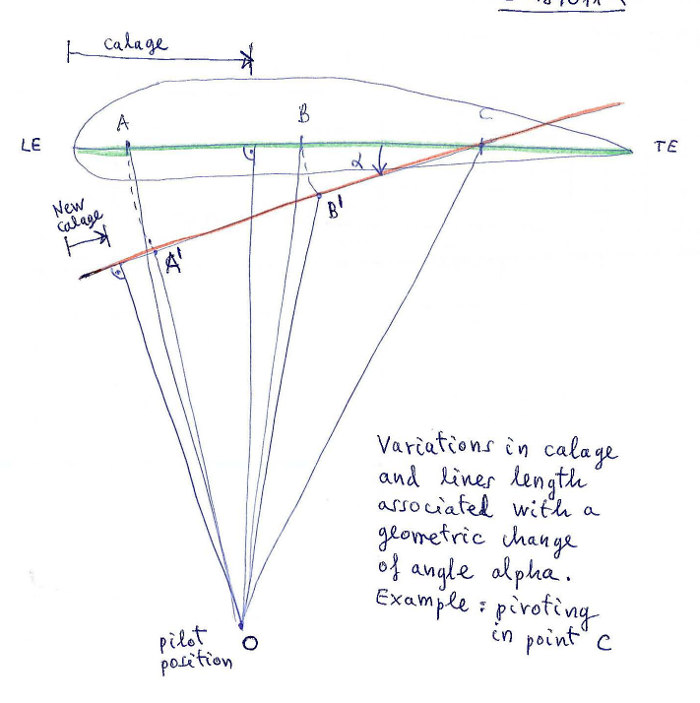

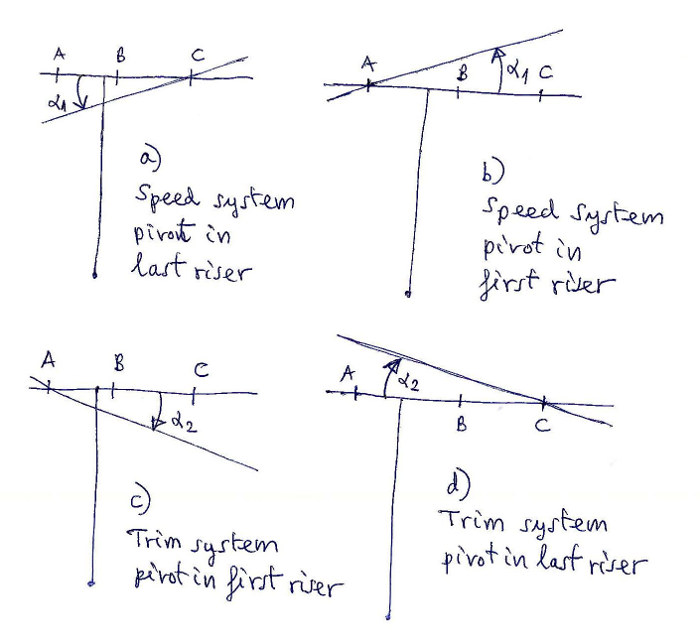

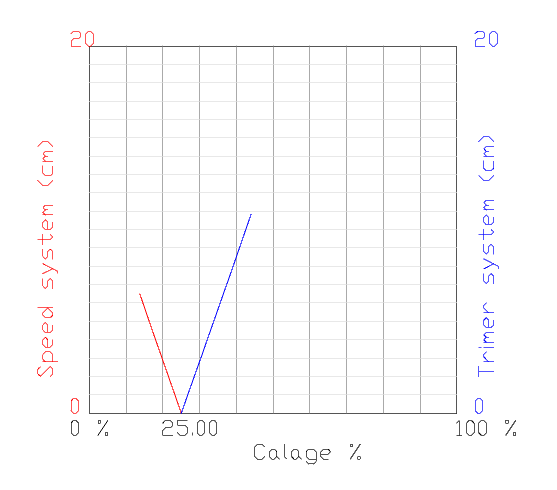

SECTION 28 PARAMETERS FOR CALAGE VARIATION

Study

the variations in the riser lengths and calage when applying speed

system or trim system. It is interesting to experiment with new calages

in prototypes or to define the speed or trim systems.

Figure 33. Principles of the study of the calage variations.