Model

|

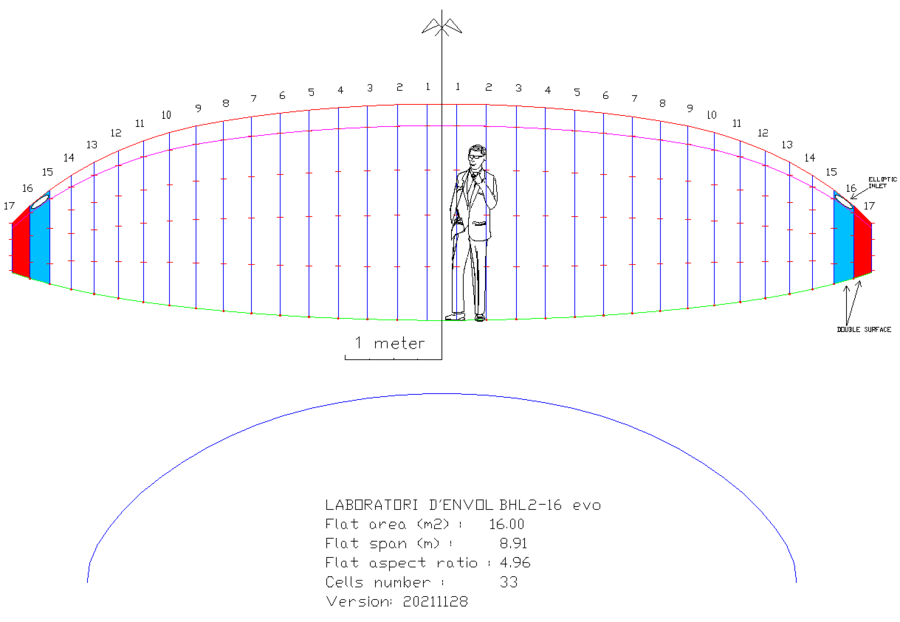

BHL2-evo 16 m2

|

Surface

|

16 m2

|

Flat span

|

8.91 m

|

Flat AR

|

5

|

Panels

|

33

|

Closed cells

|

2 in wingtip, with one elliptical air inlet

|

Weight range

|

-

|

Anchors per rib

|

4, and 3 (near tips) |

Risers

|

3

|

Top surface

|

skytex 40 gr/m2

|

Ribs

|

skytex 40 gr/m2

|

Certification

|

No

|

This

paraglider plans have been based in the BHL2-16-classic

Some small improvements now under study (for that reason the denomination "evo").

All plans in DXF and PDF ready to print in A4 here: BHL2-16-evo version 20211128 (updated to 2021 using LEparagliding 2.17 !!!)

BHL2-16 evo (version 20211128)

dxf > 2D drawings (for printing or laser cutting). Unit of the plans is cm. Scale by 10 to convert to mm (!), and 3D drawings

lep > input and output files for LEparagliding. Read lep-out.txt report. Includes source code of new lep-3.17 version.

pdf > plans report and lines schemes

pdf to print > All part ready to print in a mosaic of A4 sheets

png > some screenshots

xls > lines list in xls format

Features of this version:

This version is based on the evo version built by José Guillén, with the following changes:

- Paraglider recalculated using version 3.17 of LEparagliding

- Slightly modified panel nose shape using "1000 1.0" parameters at the end of the section 5. SKIN TENSION

- Recalculated lines using theory "3" in the section 9 SUSPENSION LINES DESCRIPTION

- Added additionals nylon rods in the area of triangle "D" to limit possible wrinkles in this area

- All parts available in PDF for A4 printing

BHL2-16 evo plans updated to 2021

BHL2-16 evo plans updated to 2021

3. Construction

This

prototype was built in november 2018 by Jose Guillén in La Palma (Canary Islands).

The constructor has already made another prototype using low cost materials.

To study the best configuration of the anchors in the area of the triangles, extensive laboratory tests have been carried out. The results are shown below. Information for editing and summary with more detail.

Materials list:

- Upper surface: skytex 40

- Ribs: skytex 40

- Circular reinforcements: nylon ripstop 68gr / sqm. Radio 8cm. Adhesive ripstop in stabilos.

- Reinforcement strips in ribs: Dacron 170gr / sqm

- Anchoring tapes: 13mm Polyester grossgrain ribbon. Breakage value + -86kg

- Nylon rods: 2.7mm nylon

- Leading edge reinforcement: 10mm dacron 170gm / sqm

- Trailing edge and stabilizers: U-shaped reinforcement with 25mm

ripstop strip and finished with 25 gr / sqm mylar strip (maybe somewhat

weak)

- Brake anchor tapes: 13mm polyester grossgrain ribbon. 20cm strips sewn with a loop at the center and at a distance of 7.5cm on each side of the rib.

- Reinforcement of the air inlet in penultimate cell: mylar 250gr / sqm

- Lines: dyneema with cover 1,5mm

- Thread: 40/3 Bonded Polyester

- Needle: 90nm Microtex

Tests:

https://drive.google.com/file/d/1ZzwXvqgbnQ60xV_Xp88PjrX-39rIanS3/view?usp=sharing

Summary table:

https://drive.google.com/file/d/1ngnpc46iyUNV7kHityY9m4ZeYXkleOn9/view?usp=sharing

Construction details:

https://drive.google.com/open?id=1wn8uhK3KaZBUkFAhDX2OVpAi-7mqYsXB

LAB NOTE: Build

a paraglider at home is a

very complicated task (even simple

skin), and requires many

hours of work. Previous experience is required, and very inventive.

As always remember that:

The free flight implies risks

that can only be known and they can be controled with a suitable formation on the part of a recognized school.

Not test wings without knowing their functioning. The

construction and test of experimental wings without certifying requires

deep knowledge of what is being made.