1. Julien

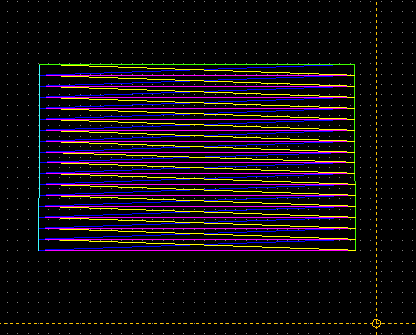

begins the design

compiling the leparagliding source code

with gfortran

in

a Mac OSX computer. After introducing the parameter

0.836 for the desired surface,

program generates the output files. One of the first difficulties is finish adjusting

DXF files generated,

using a CAD program.

The fabric covers of air intakes,

are already included in the top drawn panels? |

2. Explanation

of how put together (in CAD),

covers of the air intakes with the rest

of the top surface

of the SK panel. |

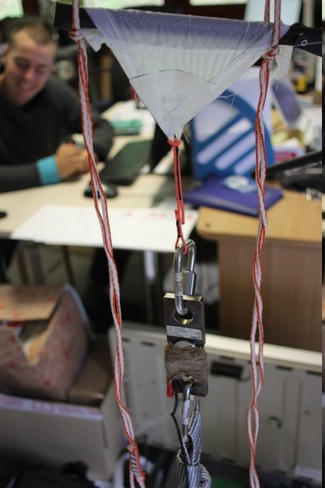

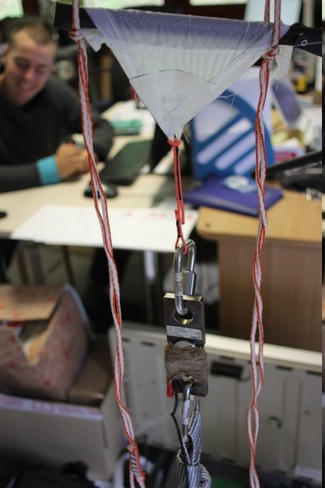

3. Test 2 assembly in Millot's Atelier:

load into triangles.

Before deciding the final

method of sewing and

reinforcement to

apply,

is always interesting perform destructive experiments with

full scale samples. |

4. Triangle

row "B", model. Before test.

Mylar reinforcement radius is 6 cm.

All these experiments, although simple, and although not exactly

reflect the real situation,

are VERY interesting.

It is recommended that all builders do similar tests,

with the most important structural elements of the wing.

|

5. Test

2 triangle after experiment.

21kg before the first deformation, 32kg break.

The mylar seam loop is intact.

The rupture took place between the mylar and

Skytex the zigzag stitching.

Slight dyssimétrie support.

|

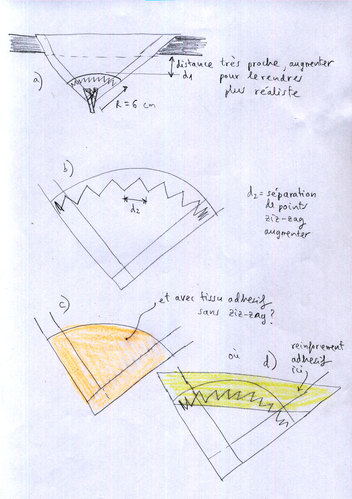

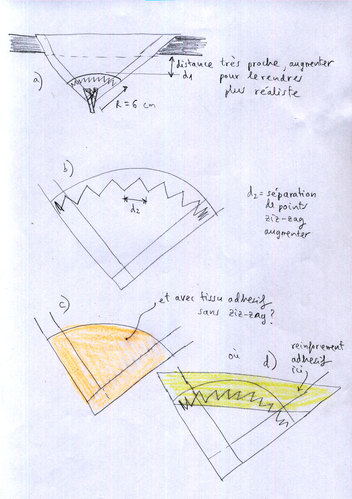

6. Some options to improve the results of experiments. |

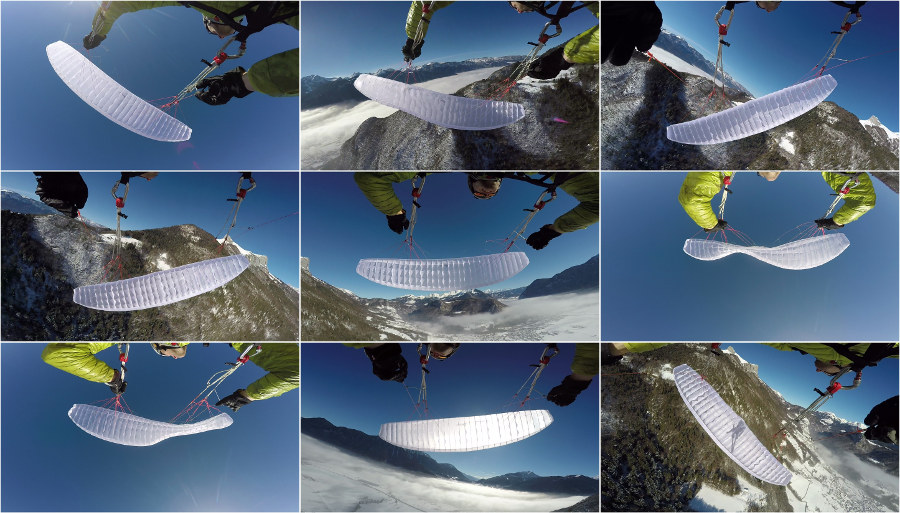

7. Test

3, before.

Mylar reinforcement radius is 7 cm.

|

8. Test 3, full

load.

|

9. Test 3. Breaking load 48kg on the zigzag stitching at the center of

ripstop first.

That is enough? The rule:

"Lines (A1 + A2 + B1 + B2) x 2, should hold 8 times the weight in flight."

Means that a in

balanced flight, in "C" and "D" rows

is almost no load,

and A3 and B3 have very little... Then only the four main lines

of each side ((A1 + A2 +

B1 + B2) x 2) should hold the full load

test of 8G. In our case

(BHL2) we have 9 anchors in A1 + A2,

and also 9 for

B1 + B2. This is (9 +9)

x2 = 36 for both sides.

36 x 48 = 1728

Kg! >

100x8 = 800 Kg

OK! But

it is always prudent to

oversize even more! |

10. Test 3 sample, after experiment.

|

11. First two panels and rib, ready to sew. Start sewing!

First, is

necessary to sew

all the reinforcements

and sawtooth edges

of the ribs.

|

12. First panels sewn. |

13. Nose detail |

14. Nylon rod inserted in the special "pocket" of the nose. |

15. "A" - end of rod detail |

16. End of the rod, softened with

heat to round shapes |

17. The other end

of the nylon

|

18. Cela commence à ressembler à une aile monosurface!

This is starting to look like a single skin wing! |

|

|