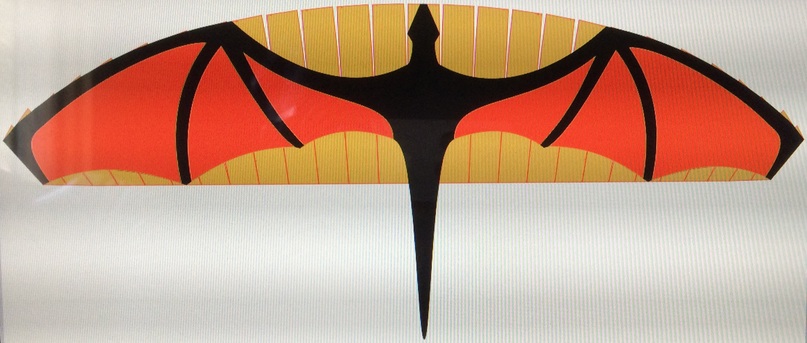

Troyer's design for gnu-A 20 m2

July 2020. Upper surface and ribs sewn. Soon the bottom surface, lines and risers.

gnuA 20 m2 is the project started by Alexander Troyer in Pittsburgh, PA (USA). Based on

gnuA1 but in size XS (20 m2) and some other modifications. Scale factor used for new new plans is about K=0.860344 (20=k*k*27,02). Download complete plans here. Read more about scale changes here.

Parameters:

27 cells

4.3 moderate aspect ratio

20 m2 surface, large (XS size)

20% thicker profile "gnuA" based on gnuLAB3 airfoil

The construction of this prototype is being using space and machinery of a "Techshop". "Techshop is like a very large factory

space, with many different machines of many types, but they don't

manufacture anything specific, it is only machinery for people to come

in and use for their own projects. You can become a member, pay a

monthly fee, and take classes on machines that are in the facility.

After being cleared for safety on the machines, a member can use them

to make whatever they want. Regarding Paragliding equipment,

they have industrial sewing machines, sergers, and "walking foot" type

sewing machines".

Some photographs on the construction

process: Construction of this prototype began in 2015. Stopped for

several years, construction has continued during the summer of 2020.

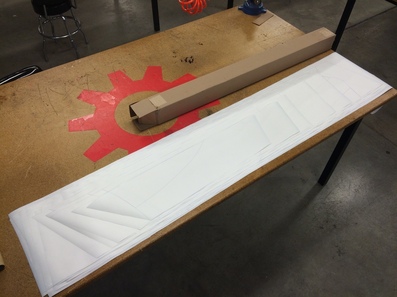

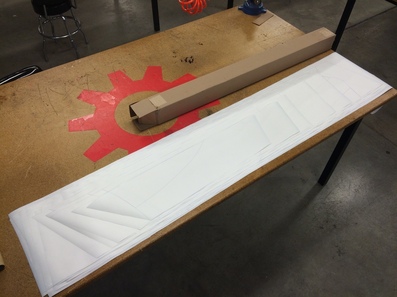

1. Panels rolled |

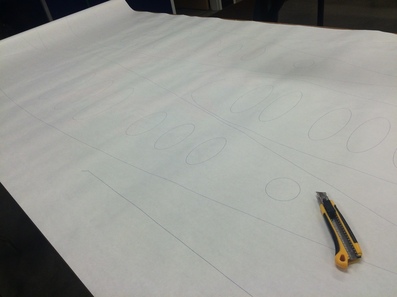

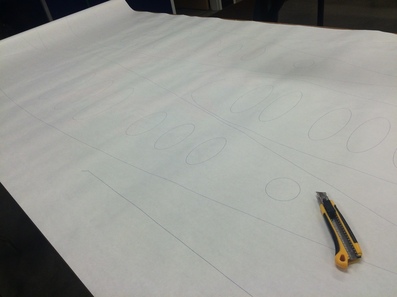

2. Plotted ribs

|

3. Ribs ready tu cut

|

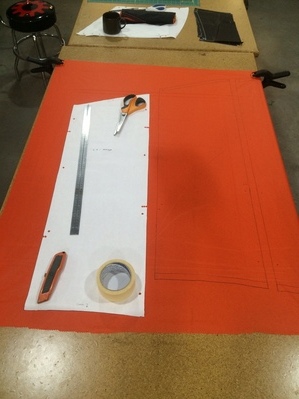

4. Panels cut

|

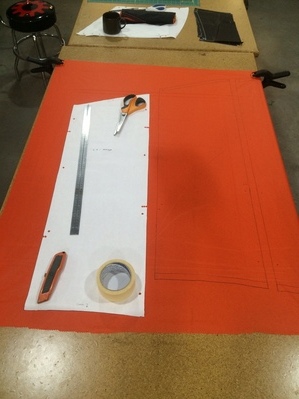

5. Rib template |

6. Colors design for lower surface, very special. |

6

|

7

|

8 |

9 |

|

|

All photos by Alexander Troyer

LAB NOTE: Build

a paraglider at home is a

very complicated task , and requires many

hours of work. Previous experience is required, and very inventive.

As always remember that:

The free flight implies risks

that can only be known and they can be controled with a suitable formation on the part of a recognized school.

Not test wings without knowing their functioning. The

construction and test of experimental wings without certifying requires

deep knowledge of what is being made.

index

laboratori d'envol