PARAGLIDER DESIGN HANDBOOK

CHAPTER 6. OVALIZATION

6.1.

Introduction

6.2

Analysis of the ovalization in

transverse direction to the cells

6.3

Analysis of the ovalization

along

the axis of the cells

6.4.

Corrections to the panels

6.1. Introduction

It is well known that the upper and lower surfaces of the cells are not

flat. Because the structure of the paraglider is textile, and that the

internal pressure is higher than outside, the cells tend to adapt a

cylindrical shape between ribs.

According to measurements made by the LE, at various paragliders, the

width of the cells in flight is around 5-6% less than the width of the

panels.

In this chapter we analyze the effect of this and its consequences on

the geometry of the panels.

6.2 Analysis of the

ovalization in

transverse direction to the cells

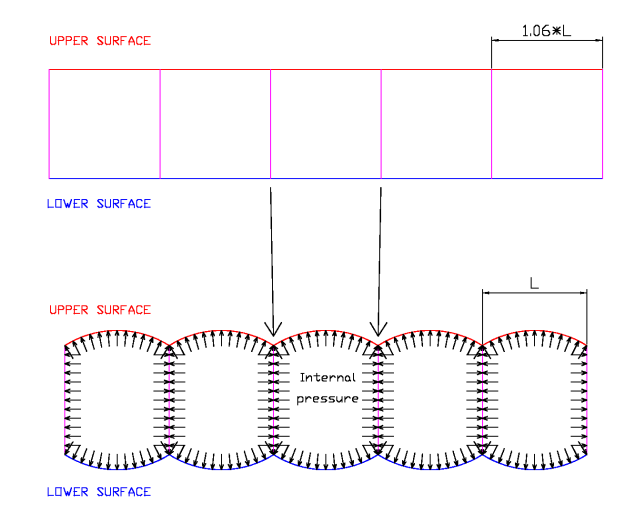

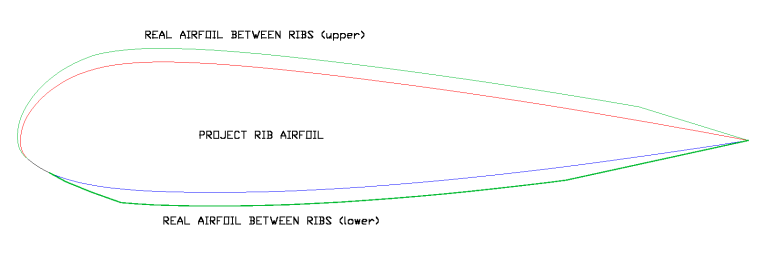

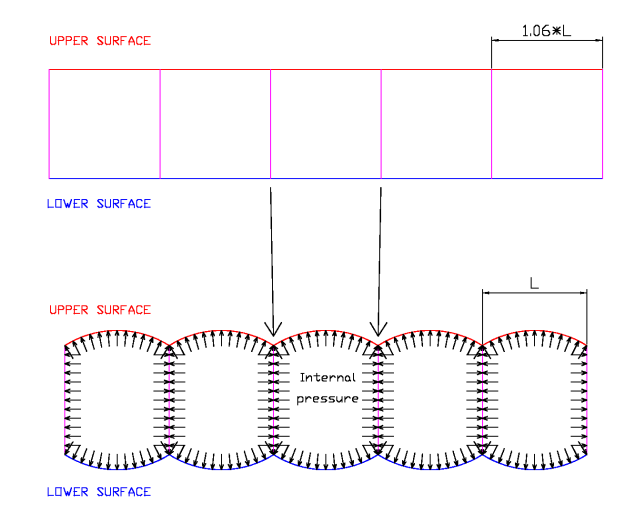

In the figure below shows the effect of a ovalization (billow) in a

cross-section to the cells.

The ribs remain flat due to equal pressure on both sides,

but the upper and lower panels adopt cylindrical shapes along them. The

degree of ovalization depends primarily on the wisespan tension.

Measurements made on various models show ovalization degrees around 6%

higher in the arco regarding the length of segment.

It is impossible to avoid ovalization and its interest lies in the need

to project the top and bottom panels adapted to it.

Fig 6.1: Ovalization in

transverse direction to the cells

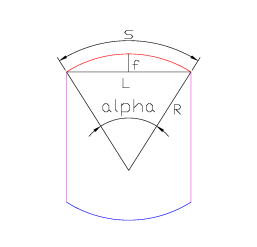

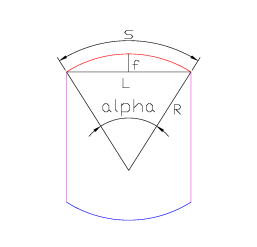

Geometry of the ovalization:

S = R * α

L = 2 * sin (α/2)

R = f + L * cos (α/2)

data: L, S

unknowns: R,f,α (solving the previous system of three equations)

Fig 6.2: Cell ovalization

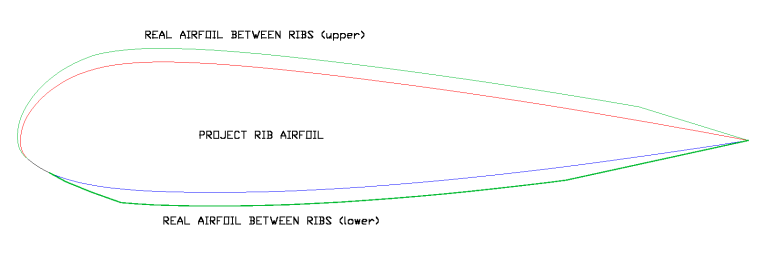

6.3 Analysis of the ovalization along

the axis of the cells

Fig 6.3: Ovalization along

the axis of the cells

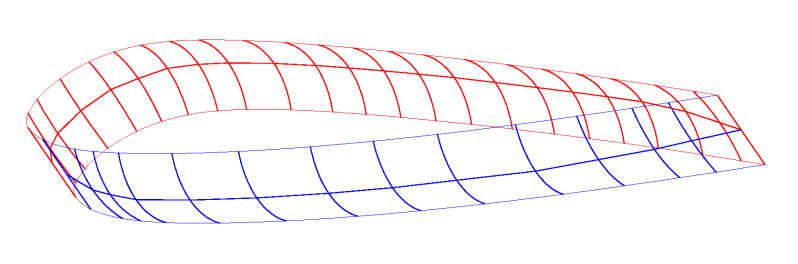

The figure below shows the effect of

ovalization lengthwise. The main

consequence is that the "virtual" airfoils contained between two

textile ribs

are different and bigger (from 18% to 21.5% in the case drawn). This

only takes into account implicitly in the design of the wing, the study

focused on the "true" or project airfoils.

An important consequence of this analysis is that the contour length of

the virtual airfoils is greater than the length of real contours of the

projected airfoils. In the example airfoil, the difference in length is

about 2.26% in the upper surface and a 0.9% on the lower surface.

Differences in the lower surface are minor, but differences on the

upper surface, are higher because of the curvature of the leading edge.

At the area of the leading edge there are two independent curvatures,

one due to the ovalization efect and another due to the curvature of

the leading edge. The

resulting surface is not developed in a flat figure. Hence the solution

is to create a micro wrinkles in the area joining the top panel with

the rib to offset the differences in length.

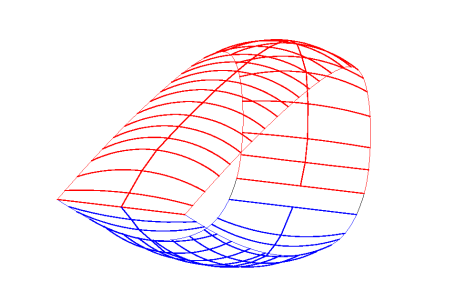

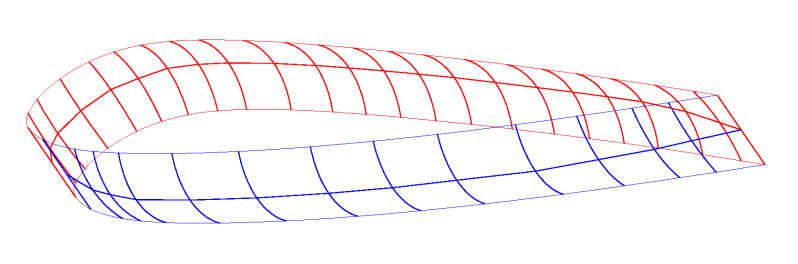

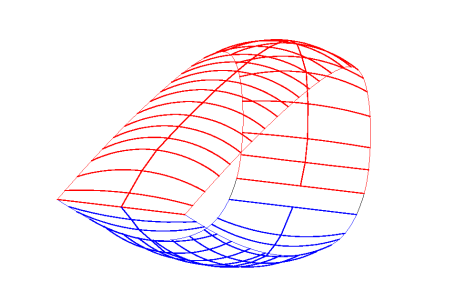

Then two figures are attached with a cell in 3D for better

understanding of the above.

Fig 6.4: Cell ovalization

Fig 6.5: Cell ovalization

6.4. Corrections to

the panels

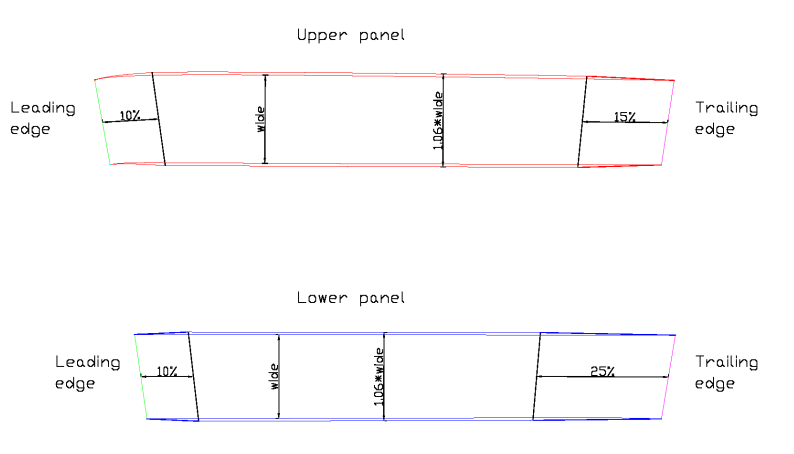

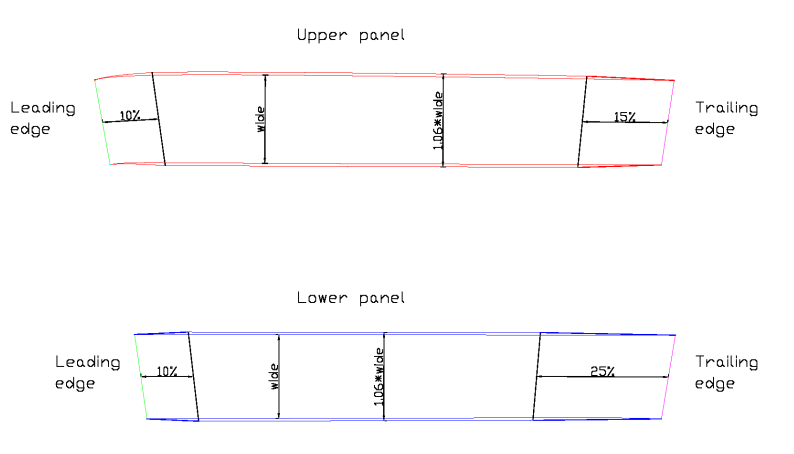

To take into account the effects of ovalization, corrections must be

made in panels obtained by the method describeb in the previos chapter.

We simpli need to increase the wide of the panels in a total of around

6% (3% on each side, and this value must be adapted in each paraglider

model).

Around the LE and TE is a linear transition of wide to reduce

ovalization and increase the sail tension in the area.

Normal values of transition points are as follows:

|

From LE

|

From TE

|

Upper panel

|

10%

|

15%

|

Lower panel

|

10%

|

25%

|

Fig. 6.6: Corrections to the panels.

index