MAILLON (QUICK LINK) STRUCTURAL ANALYSIS

1.

Introduction

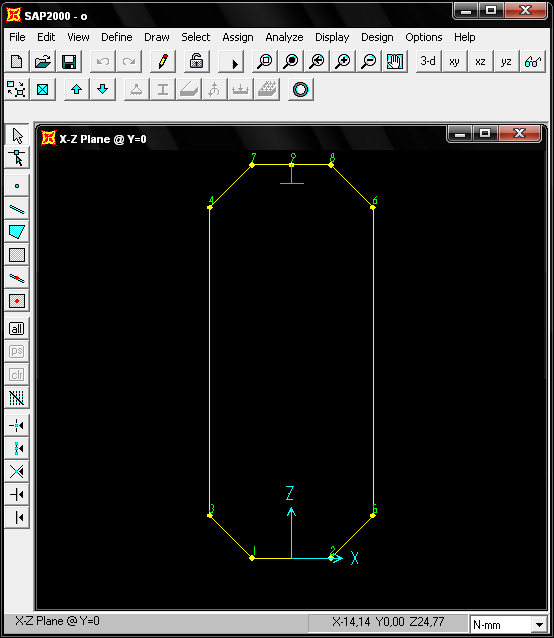

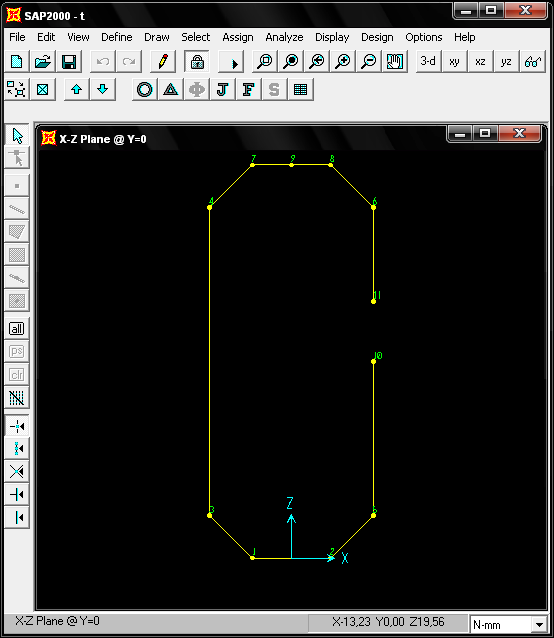

2. Geometric and mechanical specifications of the manufacturer Peguet

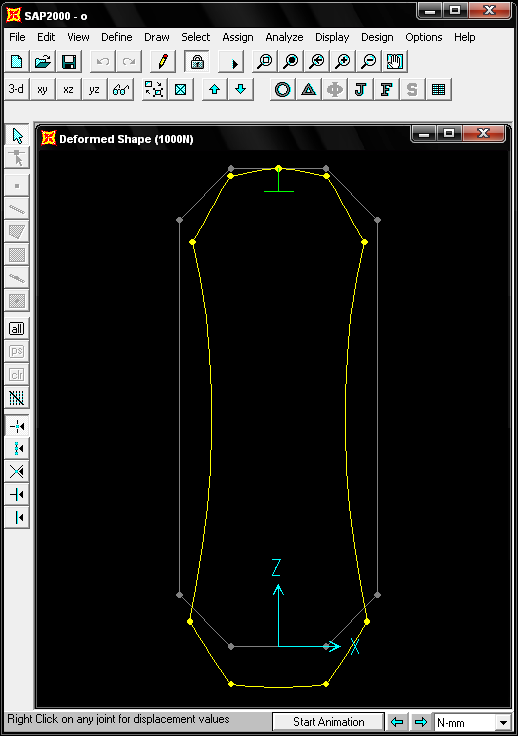

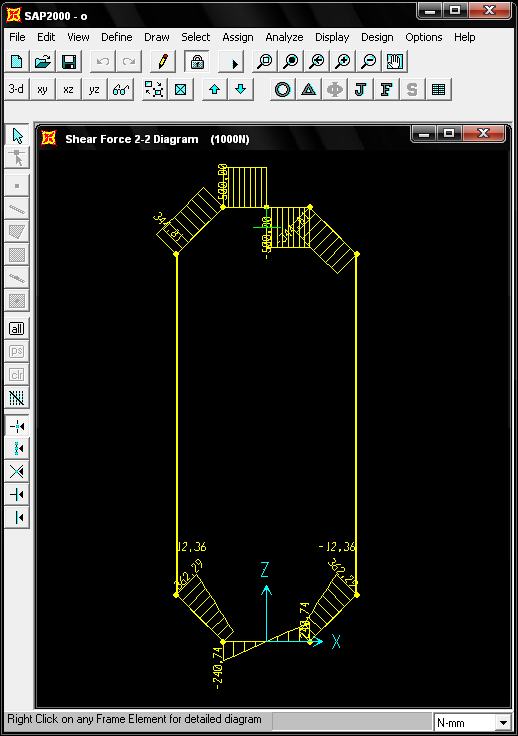

3. Numerical model

4. Graphic results

5. Numerical results

1. Introduction

2. Geometric and mechanical specifications of the manufacturer Peguet

3. Numerical model

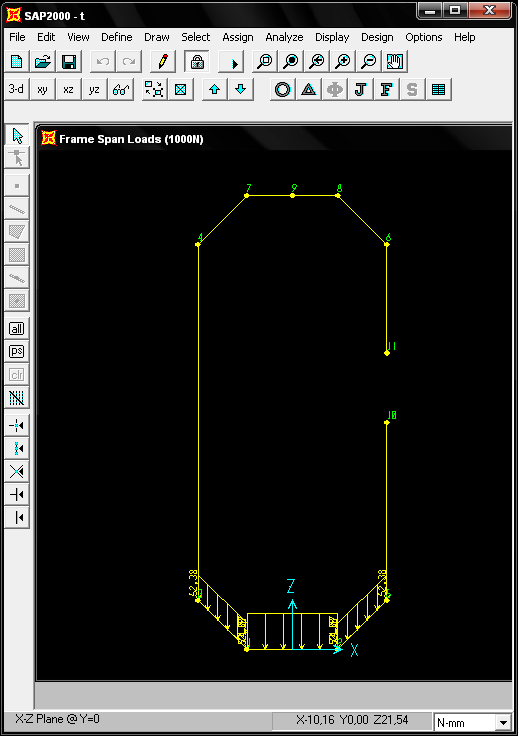

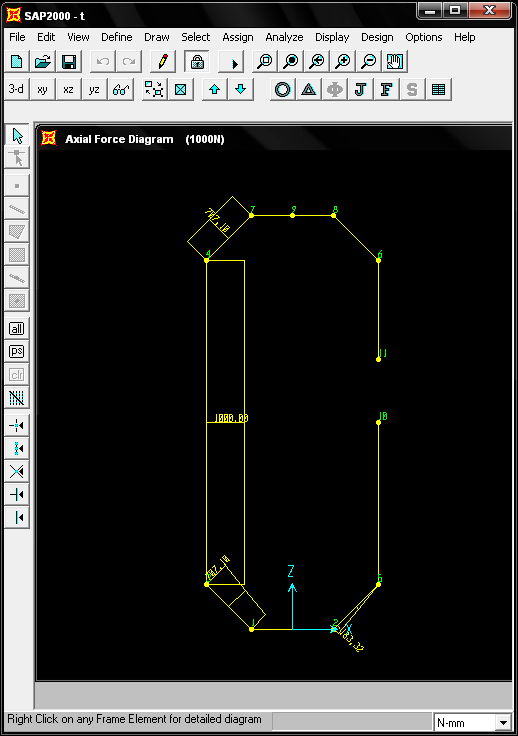

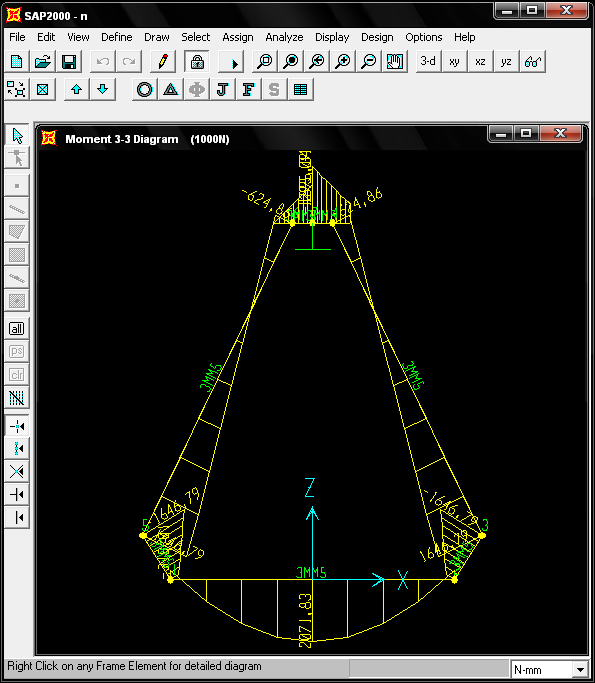

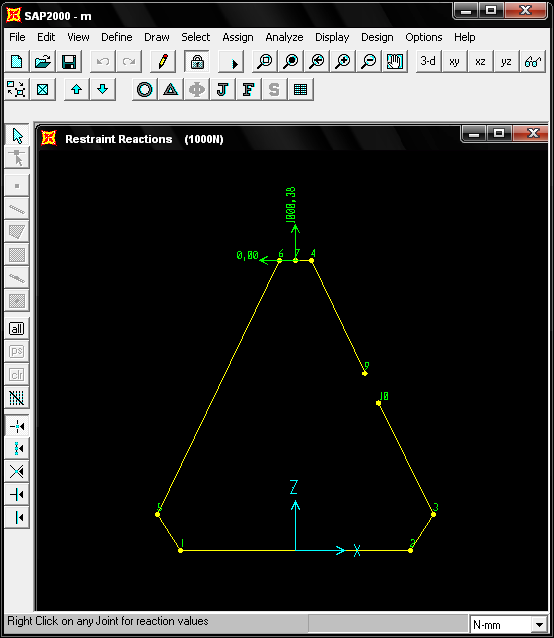

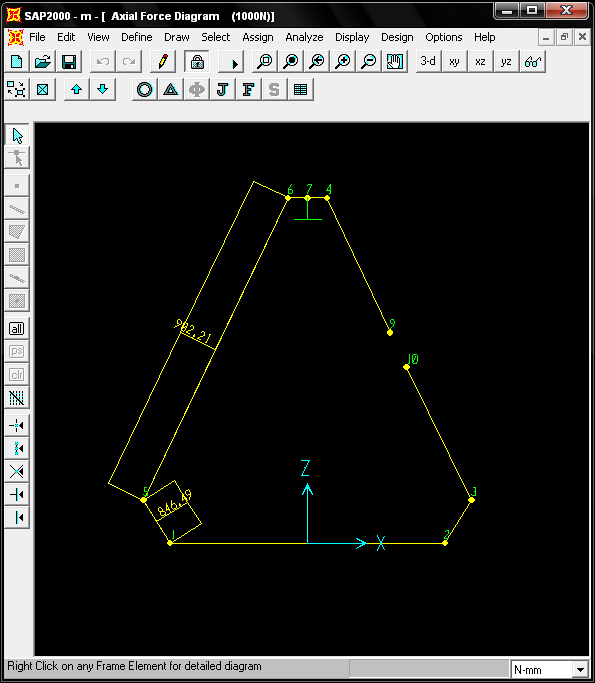

4. Graphic results

5. Numerical results

1. Introduction

The

stainless steel maillons (quick links) have been (and remains) an

essential

element for the union of the risers with paraglider lines. We have been

using

diameters of 5,4,3.5,3 mm and various shapes (oval, triangular, square

or rectangular, trapezoidal, especially ...) always for the best

adaptation and load transfer between risers and lines.

The maillon has always been a very good structurally, so it was never reason to worry about their safety, except for the need to check before each flight that are perfectly closed.

With the progressive reduction in the number and diameters lines and use of very thin dyneema risers or by weight reduction in mountain paragliders, the dimensions of maillons goes down, so it is of interest to know the behavior theoretical and practical (trials). This page details the internal theoretical efforts (axial, shear, moment) taking place in the maillon.

There remains for another study analyzing tensions in the steel section and experimentation with laboratory tests.

2. Geometric and mechanical specifications of the manufacturer (Peguet)

From Peguet : http://www.peguet.fr/

Maillon inox normal (oval):

The maillon has always been a very good structurally, so it was never reason to worry about their safety, except for the need to check before each flight that are perfectly closed.

With the progressive reduction in the number and diameters lines and use of very thin dyneema risers or by weight reduction in mountain paragliders, the dimensions of maillons goes down, so it is of interest to know the behavior theoretical and practical (trials). This page details the internal theoretical efforts (axial, shear, moment) taking place in the maillon.

There remains for another study analyzing tensions in the steel section and experimentation with laboratory tests.

2. Geometric and mechanical specifications of the manufacturer (Peguet)

From Peguet : http://www.peguet.fr/

Maillon inox normal (oval):