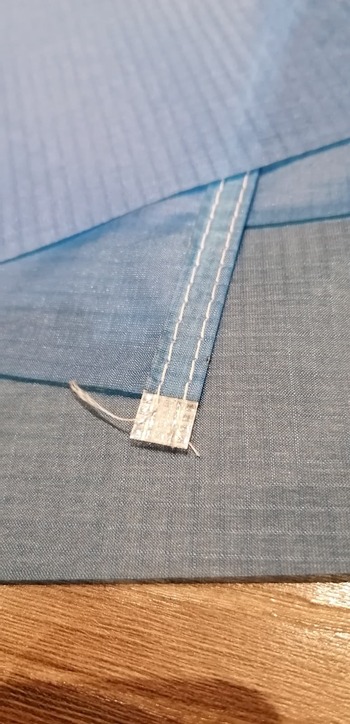

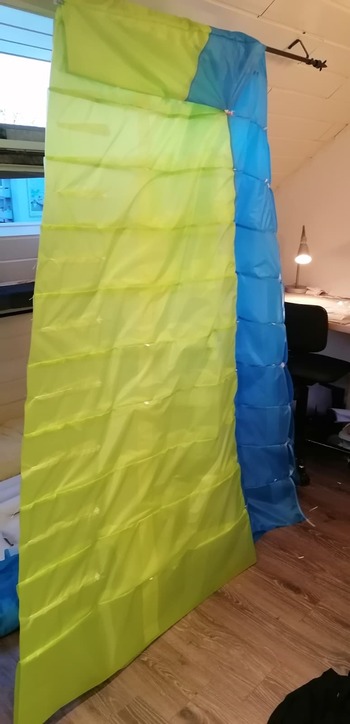

1 Skytex 38 universal

|

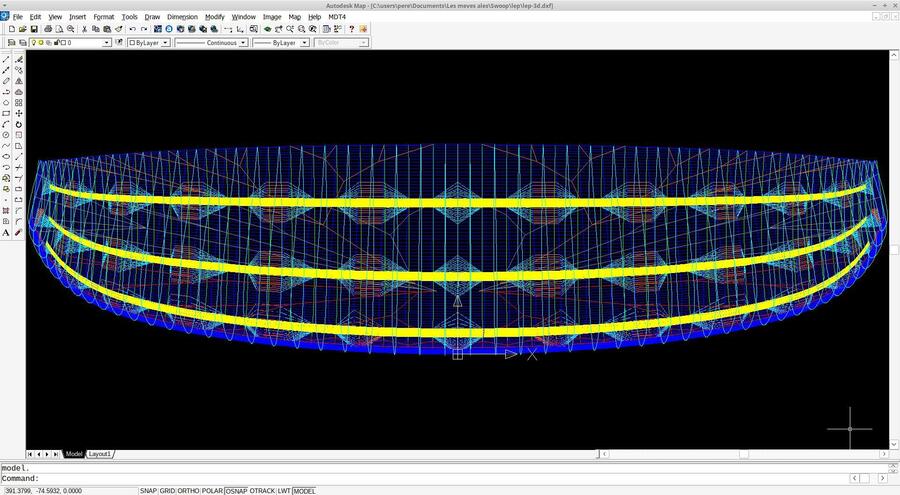

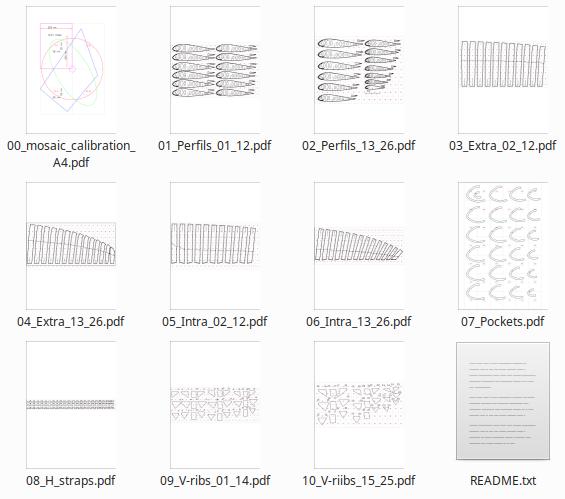

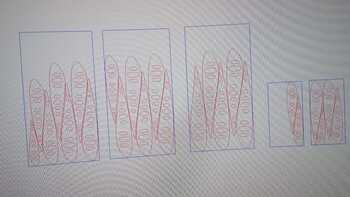

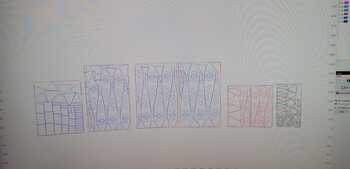

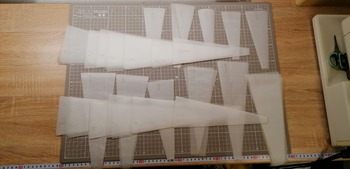

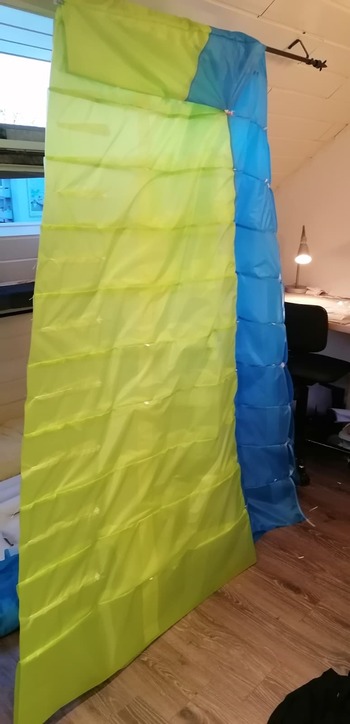

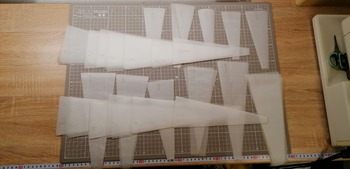

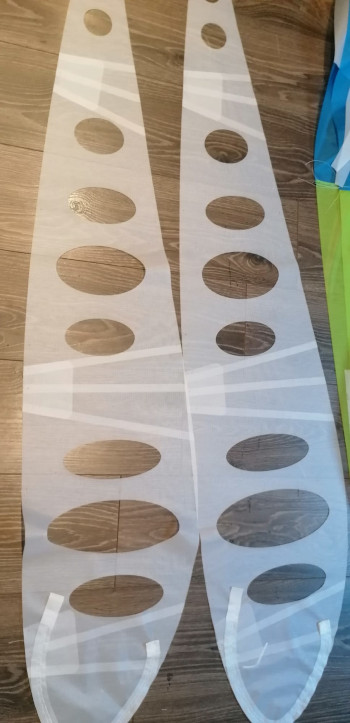

2 Preparing for cutting the inner parts

|

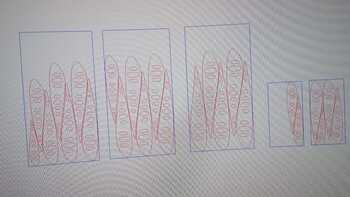

3 Good optimization!

|

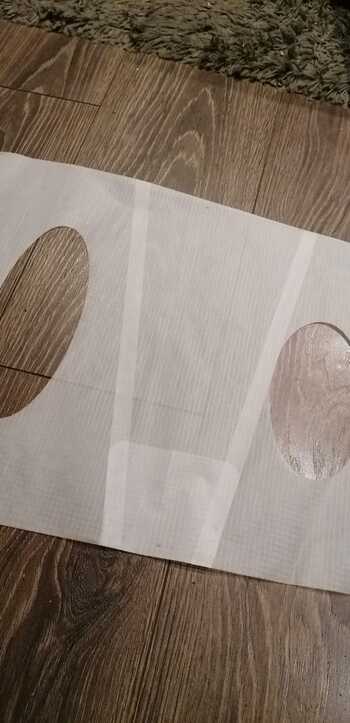

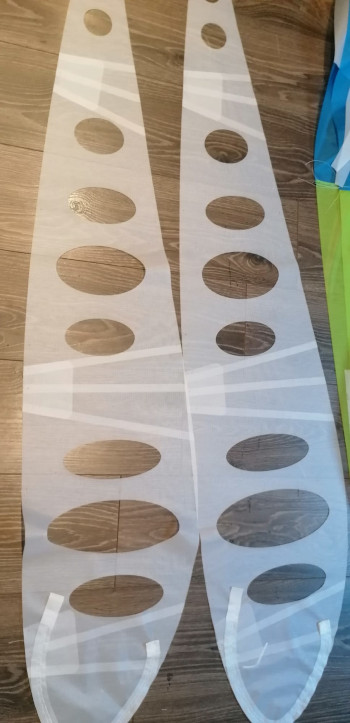

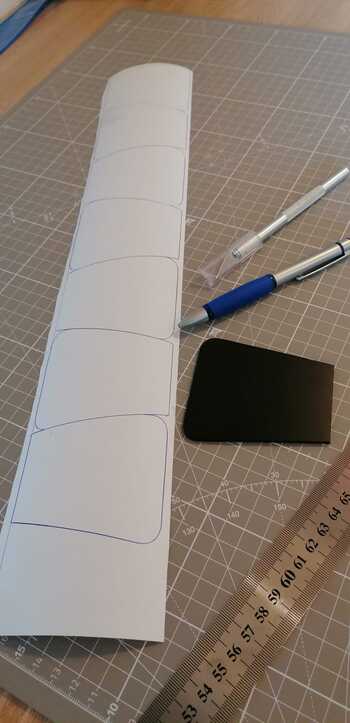

4 Mini ribs

|

5

|

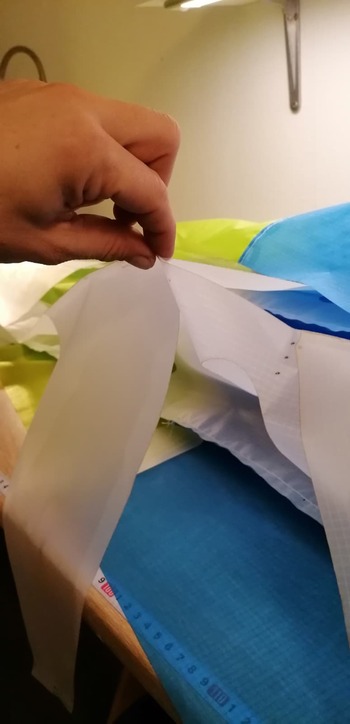

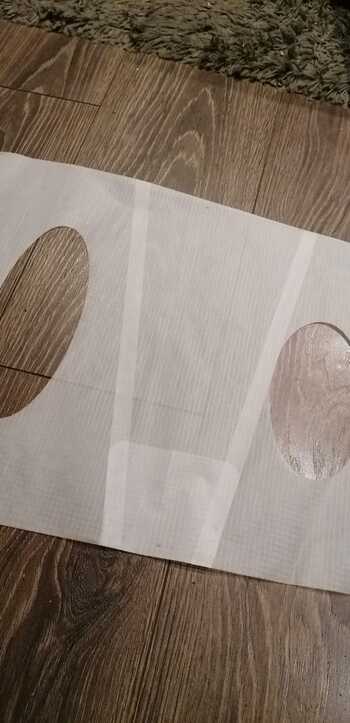

6 Rib reinforcement

|

7 Reinforcements on the ribs with anchor points. View final rib reinforcements using tree strips in photo 29 below.

|

8

|

9 Wingtips are done!

|

10 Made in Germany

|

11

|

12

|

13

|

14 Flat stripes on the bottom side

|

15 diagonal /rib/upper flat connection is glued in place

with 3mm sticky tape

|

16 Store the inner parts

|

17 Sewing wingtip

|

18

|

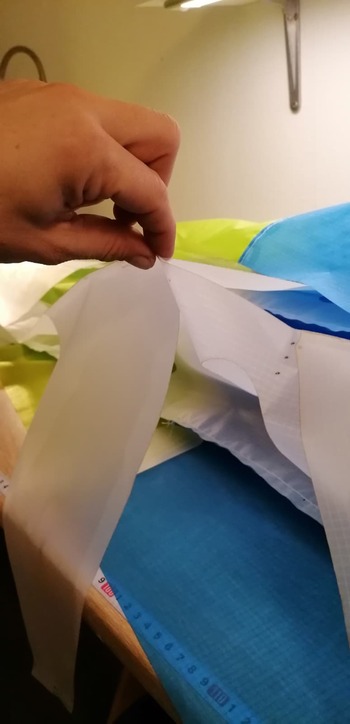

19 Layout before sewing

|

20 Rib reinforced

|

21 2 wingtip

|

22

|

23 attachment point reinforcement

|

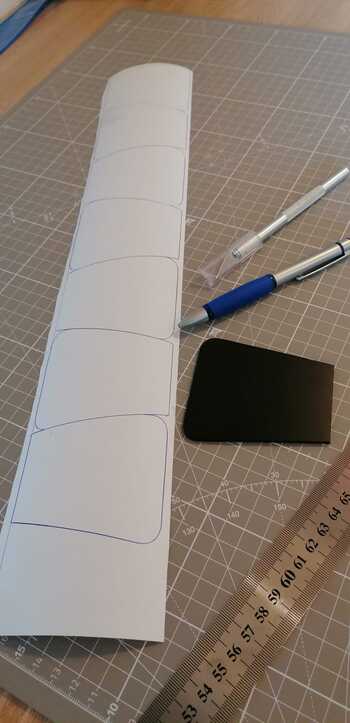

24 10mm wide mylar /fiberglass (trilam) for leading edge

fold reinforcement

|

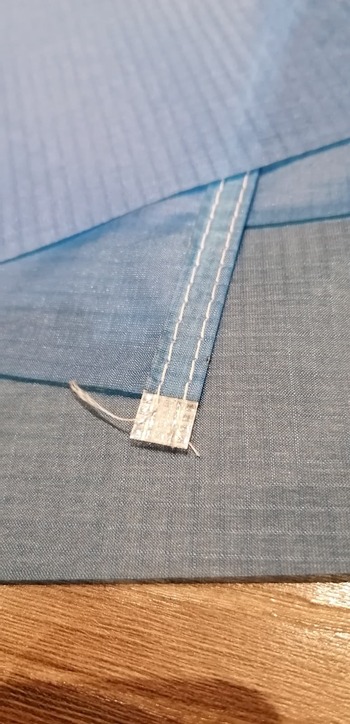

25 trilam sewn in place

|

26 15mm line attachment loop

|

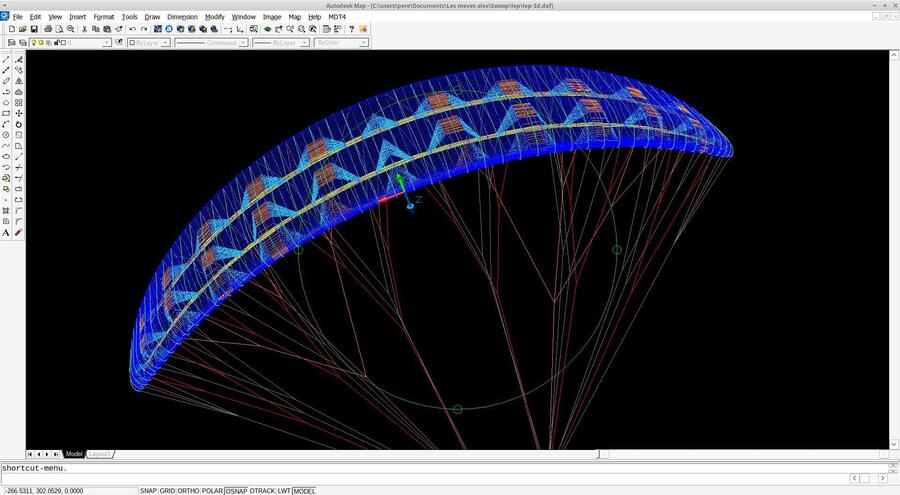

27 wing is growing fast!

|

28

|

29 Rib reinforcementss.

|

30 Going for the center connection seam...

|

31

|

32

|

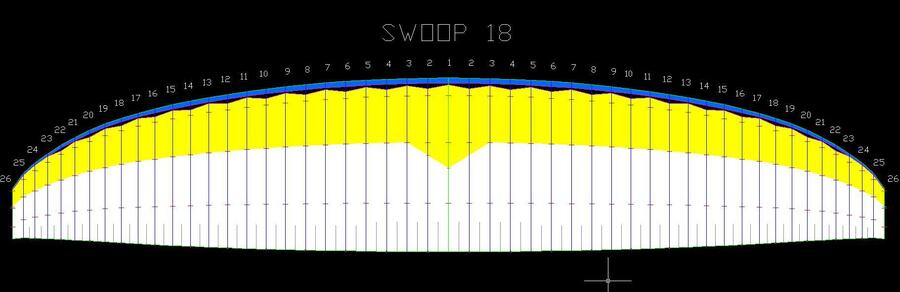

33 2025-12-31: Swoop18 canopy is nearly finished,

just have to close the trailing edge and go for some more

reinforcements/nylon rods and lines

|

34

|

35

|

36

|

37 February 2, 2026. Swoop fully completed including sail and lines! Waiting for suitable weather to do the first tests!

|

|

|

|