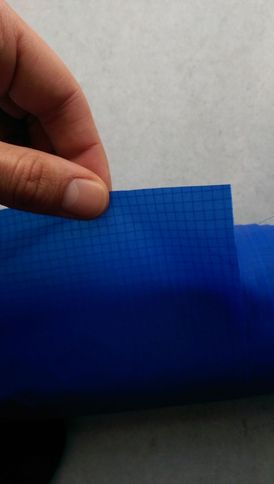

BHL2-23 "Midnight"

BARRETINA HYPER LITE 2 SIZE 23 m2

BARRETINA HYPER LITE 2 SIZE 23 m2

This single skin paraglider prototype was built by the french constructor Arnaud

Martínez, in Germany.

The paraglider has been completed in August 2015.

BHL2 23 "Midnight" flying Dune du Pilat (june 2017)

BHL2 23 "Midnight" in the Dune du Pilat (june 2017)

BHL2 23 m2 Dune du Pilat (june 2017)

BHL2-23 Midnight

The paraglider has been completed in August 2015.

BHL2 23 "Midnight" flying Dune du Pilat (june 2017)

BHL2 23 "Midnight" in the Dune du Pilat (june 2017)

BHL2 23 m2 Dune du Pilat (june 2017)

BHL2-23 Midnight

1. Technical

specifications BHL2 23 m2

"Midnight"