STRESS-STRAIN RIPSTOP CURVES (I)

The stress-strain test is a classic in the science of strength of materials, because it allows accurately knowledge of its elastic properties.

Why not apply it to the tissue of paragliding? This is precisely what we have done in the laboratory. This trial, together with the porosity, allowed us to validate the tissue used in the Ascender. In general, this test should be done on any unknown fabric, or with little data from the manufacturer, or to control its strength.

Can not be done on paragliders in use, because it is a destructive test and requires a portion of tissue.

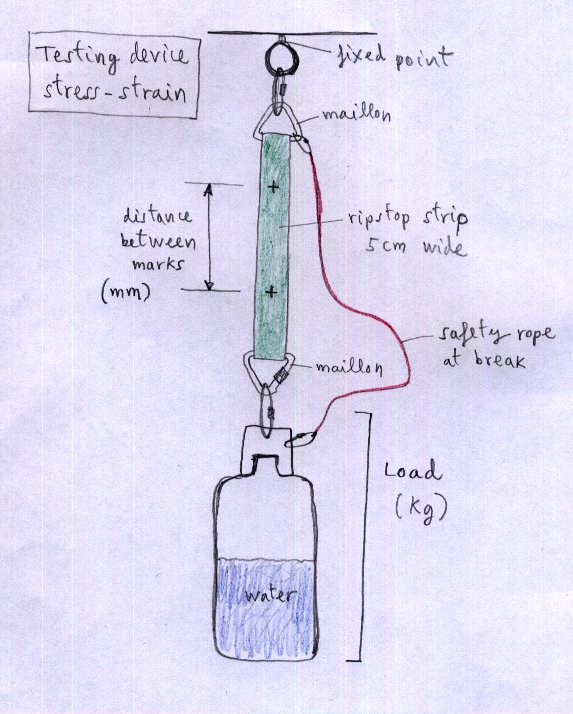

Fig 1. Testing device

The test system consists of loading progressively a ripstop tissue strip of 5 cm wide, and simultaneously measuring the distance between two reference points marked on the tissue, and the applied load. The trial continues gradually until rupture of the material, or to the point where you want to start the unloading and check for the permanent deformation.

The result is a table with the pair of values (distance (mm), load (kg)). For a stress-strain curve normalized, these values are converted as follows:

Stress (kg/cm) = Load (kg) / 5 cm

Strain = ( (Distance / Initial distance) ) -1 )

Strain = ( (Distance / Initial distance) ) -1 )

2. Practical testing

Some photographs taken during the tests:

3. Stress-strain curves

Data sheet (format openoffice).

4. Conclusions

Some photographs taken during the tests:

Eolo 42 g loaded at 22 kg |

Skytex 45 broken at 30 kg |

Eolo 60 g before test |

Eolo 60 g loadet at 8+8+8+6.5= 30.5 kg |

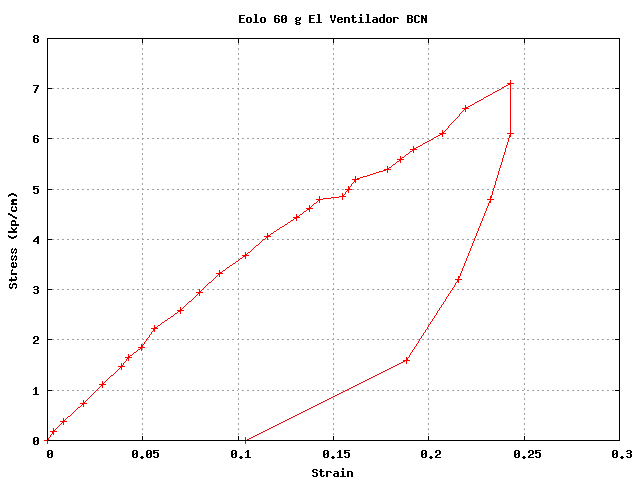

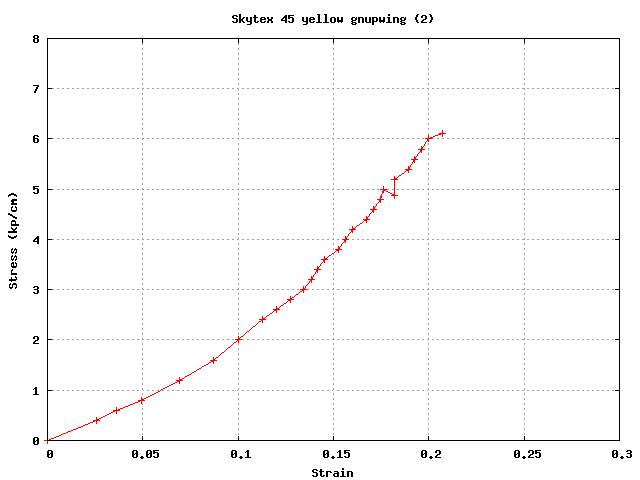

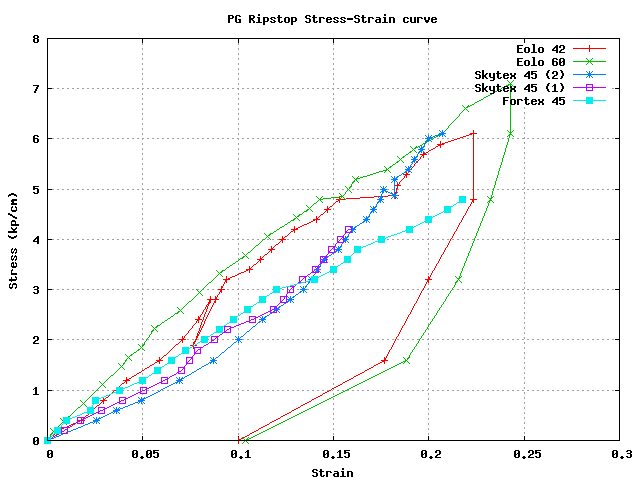

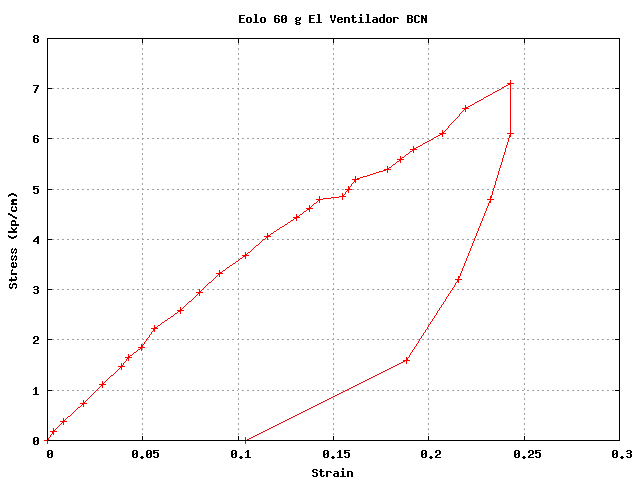

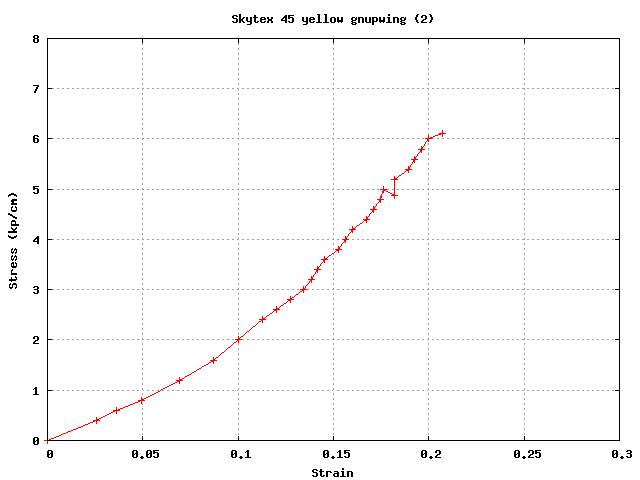

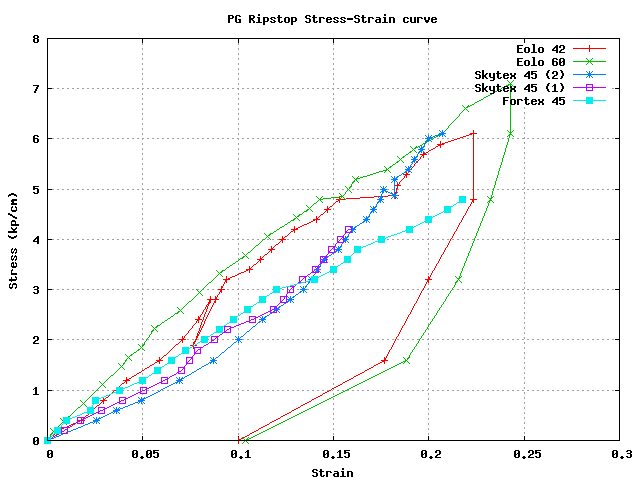

3. Stress-strain curves

Data sheet (format openoffice).

4. Conclusions

-

- The maximum loads in the tissues tested are between 4 and 7 kg/cm (20kg and 35 kg per strip 5 cm wide).

- The fabric deformation at maximum load reached 20%.

- The permanent deformation after unloading, when arriving near the rupture, reaches 10%.

- The slope of the curve in its initial section, is corresponding to the deformation module E, according to Hooke's law: σ = E x ε

- The experiment is interesting, because each tissue has a curve that identifies itself, and tissues can be compared by their characteristics curves.

Note: The data presented here are not official, and do not represent

the average characteristics of the tissues.

The results have only theoretical interest

The manufacturer should be consulted for precise details of each of the different grades manufactured

Home LE

The results have only theoretical interest

The manufacturer should be consulted for precise details of each of the different grades manufactured

Home LE